The effect by a catalytic Fe interlayer on the formation of graphene onto a diamond (111) substrate, has been studied by using DFT calculations under perodict boundary conditions. With varying the Fe interlayer thickness from two to five atomic layers, geometry optimized diamond//Fe//graphene multilayer models were obtained. A general result was that the Fe atoms are ontop positioned on both the graphene carbon atoms and on the diamond carbon atoms. Moreover, both the interfacial diamond//Fe and Fe//graphene adhesion energies were calculated and compared. As a result, the interaction between graphene and the iron layer, which was indentified as of an electrostatic nature, was found to be weak (-12.3 to -10.5 kJ/mol per graphene C atom) and propotional to the thickness of the Fe layer. The thicker the Fe interlayer, the stronger was the adhesion energy. On the contrary, the adhesion energy for the binding of a Fe layer on the diamond substrate was calculated as much stronger (-124.5 to -109.0 kJ/mol per diamond C atom), and following an inverse correlation. The thicker the Fe interlayer, the weaker is the interfacial adhesion energy. Calculations of electron density differences and partial Density of States (pDOS´s), will further support the results of a quantum size effect of the iron layer.

The corrosion of mild steel (MS) was studied in Red Sea water. The effect of disodium ethylenediaminetetraacetic acid salt (Na-EDTA) as an inhibitor in this medium was also studied. Weight loss, and Open Circuit Potential (OCP) were used as the tools of the study, where the Fe-surfaces before and after corrosion were examined using Scanning Electron Microscopy (SEM). We notice that, the corrosion reaction was reduced when Na-EDTA was added to the medium. As the concentration of Na-EDTA was increased, the corrosion rate decreases. It seems that, certain barrier of Na-EDTA adsorbed on Fe-surface which isolate the corroded medium from Fe-surface. The adsorption phenomenon was studied by different adsorption isotherms and found to fit well with Langmuir and Temkin. Thermodynamic parameters were determined from Arrhenius and Eyring equations. SEM shows the decrease of the roughness of MS after adding Na-EDTA.

Kashif Nazir and Anwar Khalil Sheikh

Losses to society in term of life and property due to catastrophic failure of pressure parts are often traced to defective welds. Whereas the code/standard are collaborative experiences from welders and consumers voice which have recommended broad process parameters tolerance for the acceptable product (weld) quality but within that recommended window still, there is a scope to find the further narrowed down optimum or near optimal process parameters settings and authors researched narrowed down the code acceptable limits to find the best weld condition.

Moreover, major advances and researches are done in welding science and technology in recent years where researchers and scientists have focused mostly on welding works which were executed in the welding shop. The author studied on the FCAW which is widely used for welding in a remote area such as welding in the windy and dusty environment for cross country pipelines where the arrangement of welding shop is not economically feasible.

Fabricators and contractors consistently report that their welding issues are the need to reduce the welding costs due to rework of defected welds and to improve the welding productivity. The research is made to optimize the FCAW base on industries problems.

Adar Karagöz, Erman Demircilioğlu and Cihan Karademir

Multi-walled carbon nanotubes (MWCNT) have been investigated in this research as being an electrical heating material in mortar. This research studies the self-heating of conductive mortar pastes with MWCNT materials by the application of an electric current. The main parameters studied are: percentage of MWCNT materials, electrical resistance, power consumption, increased temperature per minute and maximum temperature rise.

Three MWCNT reinforced cement based mixtures and reference mortar were designed. Four samples were cast and cured. Afterwards, tests were run under equal currents and the temperature of the specimens was registered. During this time, temperature increase per minute and maximum temperature rise was calculated.

Laura GarcÃÂa, Javier Criado A, Fernando Penco, Growene W Queirós, José M Gómez de Salazar and Antonio J Criado

Archaeometallurgy has shown that the passage of long periods of time - centuries and millennia - produces very characteristic structures and morphologies in hypo-eutectoid steels. It is the evolution of contemporary steel structures that over time evolve into thermodynamic equilibrium at room temperature. These morphologies have been studied by us over a long period of time. In this research we present a thermal treatment of simulation of the structures related to the incineration of pre-Roman archaeological pieces from the 3rd to the 1st century BC. With this longlasting thermal treatment of up to 10,000 hours of heating to 300°C, prior heating to 950°C and abrupt cooling, we intend to obtain iron carbide structures of similar morphology to those observed in pre-Roman archaeological pieces.

Tai-Chen Kuo, Chao-Yi Lin and Wen-Hsi Lee

The strain engineering of the source/drain has been applied from the N45 till now. When the size of the transistor is reduced continuously, it is necessary to increase the germanium concentration to add more stress, but it reduces boron concentration with increasing the germanium. The use of ion implantation compensates for the boron concentration well, while caused some problems, including ion implantation damage, diffusion, and activation of dopant ions. Therefore, to activate dopants by tuning different Ge content or pre-amorphized implantation. In the meantime, in order to cope with the low-temperature process for Ge, microwave annealing was added to compare with rapid thermal annealing.

In this paper, silicon germanium film covered with Si, Ge and uncovered before ion implantation is investigated. The sample deposit with Ge capping layer undergoes surface loss after annealing, and the Si capping layer can effectively prevent the surface from roughness. Next, the trend of the Boron activation in SiGe alloys with different Ge contents is discussed. The boron activation level increases with the increase of Ge content, but the trend will gradually saturate, and even segregate to cause the device degradation. From 20% to 40% Ge with a dose of B (ISD 3.2 x 1020 cm-2+I/I 3 x 1015 cm-2 and 2 x 1015cm-2, Si0.65Ge0.35 is an optimum value. For dopants activation in SiGe material, the thermal process is dominant, but the influence of SiGe composition is gradually increasing. The control of in-situ doping concentration has become an important issue. Finally, the diffusion and electrical properties of various species pre-amorphized implantation, repair implant damage by microwave annealing and rapid thermal annealing are investigated. Boron distribution, sheet resistance, and mobility were checked to infer the activation level and defect evolution. The best performance is the sample with Ge PAI, and it can effectively enhance the boron activation by microwave annealing while preventing the diffusion.

AL-Kurdhani JMH, Huajun Wang and Elrasheed Elhaj

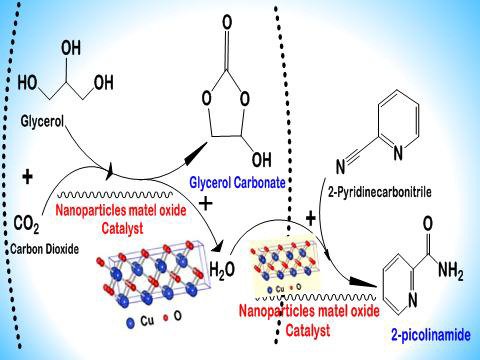

Four types of metal oxide nanoparticle catalysts (La2O3, NiO, CuO, and Co3O4) are prepared by precipitation method and used for the synthesis of glycerol carbonate from the direct carbonylation of glycerol and carbon dioxide in the presence of dehydrating agent and solvent. The effects of calcination temperatures, dehydrating agents, and reaction parameters on the conversion of glycerol and yield of glycerol carbonate are investigated. XRD, FT-IR, SEM, BET, CO2-TPD, H2-TPR and ICP-MS are used for the characterization of the prepared catalysts. It is found that the efficient catalyst for the carbonylation of glycerol should have not only large amount of basic sites and surface area, but also high redox ability and oxygen vacancy. CuO with calcination at 400°C exhibits higher catalytic activity and the best dehydrating agent is 2-Cyanopyridine. The active site of CuO catalyst may be crystal face (111). Under condition of 150°C, 4 MPa, 5 h, the glycerol carbonate yield can reach about 40%. The catalyst can be reused five times with little loss of activity and can be easily regenerated by calcination at 400°C.

The OCC products have the potential to be used in many industries due to the versatility and low cost of the manufacturing process. The process produces single crystal/unidirectional net, and near net products with excellent surface quality, controlled microstructure and enhanced properties. This article is an overview of the progress in OCC process since its inception in manufacturing of metallic components. The process, product range, potential and limitations are outlined. The process is now commercialized; and products for electronics, medical, joining, hard facing, shape memory, etc., can be fabricated. However, according to expectations, its use is still limited and potential applications including fabrication of structural materials for aerospace and automobile applications, production of large size ingots, purification of alloys and silicon crystal growth remain to be explored.

Milad Tajik, Mahdi Yoosefic and Laleh Adlnasab

Journal of Material Sciences & Engineering received 3677 citations as per Google Scholar report