Research - (2020) Volume 7, Issue 4

Received: 21-Jul-2020

Published:

18-Sep-2020

, DOI: 10.37421/2380-2391.2020.7.273

Citation: Mahdi Haghani and Shahram Daneshpazhuh. “ A Novel Multi-Step Purification Method for Production of Profitable Food Grade Phosphoric Acid and Ammonium Based Fertilizers from a Sedimentary Ore” J Environ Anal Chem 7 (2020): 273 doi: 10.37421/jreac.2020.7.273.

Copyright: © 2020 Haghani M, et al. This is an open-access article distributed under the terms of the creative commons attribution license which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

Effective parameters on producing food grade phosphoric acid and consequently di-ammonium phosphate fertilizer from a sedimentary phosphate ore were investigated in this study. The ore characterization analysis was performed and revealed that there were 32.32% of P2O5 along with some elements such as iron, calcium, magnesium, chlorine, fluorine, arsenic and lead in the ore deposit. Following the initial washing experiments, two methods were used to dissolve ore and multi-step purification of phosphoric acid was performed to remove impurities. Accordingly, the solution had been concentrated using solvent extraction system. The extractant was prepared in a novel way from three-to-one mixture of Tributyl-phosphate and Isopropyl-alcohol. Kerosene was used as a solvent in these experiments. For optimization, the experiments were performed using statistical design method by DX7 software and then high purity phosphoric acid was obtained. Finally, the obtained phosphoric acid was converted to ammonium based fertilizers during optimization tests.

Phosphoric acid • Diammonium phosphate • Monoammonium phosphate • Solvent extraction • Purification • Food grade • DX7

More than 240 million tons of phosphate ore are extracting annually worldwide [1]. Economical ores mainly contain Apatite, Monazite, Allanite, Bastnasite, Xenotime and even Glaucophane minerals. The final phosphate products are generally traded in three different categories. These categories include phosphate processed ore, phosphoric acid and MAP, DAP, TSP and SSP fertilizers [2]. Producing phosphoric acid in hydrometallurgical process is significantly more economical than pyrometallurgical procedure [3]. The tricalcium phosphate that exists in phosphate rocks reacts with sulfuric acid and produces insoluble phosphoric acid and calcium sulfate salt (gypsum). The thermal procedure has been obsoleted because of high energy consuming rate [4]. There are three kinds of processes based on the situation of produced calcium sulfate; Calcium sulfate can be obtained in hydrated, hemihydrate and dehydrated ways [5,6].

Di-ammonium phosphate and mono-ammonium phosphate are the most valuable and widely used fertilizers in agricultural industry [7]. One of the most important differences between di-ammonium and mono-ammonium phosphate is their strength of acids and bases (pH) [8]. Therefore, their formation conditions in the reactions are usually regulated by pH control. The key point here is achieving techniques appropriate to producing food grade fertilizers and also those fertilizers that have standards of agricultural industry from diverse mineral resources [9,10].

In order to perform experimental tests and ascertain particle size distribution, 50 Kg of a sedimentary phosphate which had been prepared by one-step crushing and grinding, has been analyzed. Based on the outcomes of the sieve analysis the sample’s d80 was calculated and resulted in 54 microns. Figure 1 shows the sieve analysis plot of phosphate deposit sample.

In order to determine the amount of chemical compounds, XRF analysis was performed on 100 grams of representative sample. The results of this analysis can be seen in the Table 1.

| Composition | % | Composition | % | Composition | % |

|---|---|---|---|---|---|

| Na2O | 0.57 | K2O | 0.024 | SrO | 0.077 |

| MgO | 1.49 | CaO | 52.3 | Cr2O3 | 0.06 |

| Al2O3 | 0.23 | TiO2 | 0.23 | Cl | 0.3 |

| SiO2 | 1.16 | V2O5 | 0.039 | Fe2O3 | 7.7 |

| P2O5 | 32.32 | MnO | 0.013 | SO3 | 0.29 |

The XRD analysis indicated the existence of minerals as, Fluorapatite, Hematite, Magnetite, Montmorillonite, Calcite, Talc, Monazite, and Allanite in the mineralogical structure of phosphate deposit (Figure 2).

The purification and fertilizer production tests have been performed using One Factor at a Time method. The full factorial design method has been applied to statistical design for solvent extraction section. The pH experiment range has been considered in three levels of 0.5, 1 and 1.5 in the statistical design of experiment. Concentrations of phosphoric acid have also been selected as 22%, 25% and 28% (by weight) for aqueous phase (pH=1 and phosphoric acid concentration=25% have been considered as central points of experiments). Furthermore, the temperatures of 25°C and 45°C and the organic phase concentrations of 60% and 80% have been considered. Also, all the experiments have been set to last for 30 minutes. In these experiments, a mixture of three to one volumes of Tri-butyl phosphate and Isopropyl alcohol as extractant was prepared and kerosene was used as solvent. It should be noted that, in order to prepare phosphoric acid with mentioned concentrations, a part of the solution was evaporated. The pH values of experiments have been set by hydrochloric acid. All volumetric measurements were done using mass and specific gravity of the materials.

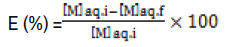

The extraction percentage (E) is determined using the following equation:

Where, [M]aq.i and [M]aq.f represent the initial and final concentration of the element in the aqueous phase, respectively.

In order to produce phosphoric acid, during dissolution of phosphorus, other impurities are mainly dissolved into the filtrate; Impurities like Iron, Arsenic, Lead, Cadmium, Mercury, Chlorine, Fluorine and organic acids which reduce the quality of product. Chlorine is one of the most important impurities which can be costly removed in case of existence high concentration in filtrate [11].

Therefore, the water based washing method, has been used to minimize the amount of chlorine entering into the filtrate because of the high amount of chlorine in the primary ore. The test conditions and results are shown in the Table 2. According to the table, dissolution efficiency of chlorine in water increases with increasing temperature. The minimum dissolution rate at ambient temperature (25°C) was 43.3%. Non-dissolution of chlorine beyond the obtained efficiency can be attributed to its involvement in the mineralogical structure of the deposit. The analyses have been performed using the titration methods in this section.

| Parameters/Row | Dissolution Recovery (%) | L/S Ratio | Percentage of Chlorine After Washing (%) | Percentage of Chlorine Before Washing (%) | Time (minutes) | Temperature (°C) | Dissolution Recovery (%) |

|---|---|---|---|---|---|---|---|

| 1 | 58.6 | 3 | 0.124 | 0.3 | 45 | 60 | 58.6 |

| 2 | 56 | 3 | 0.132 | 0.3 | 45 | 45 | 56 |

| 3 | 43.3 | 3 | 0.17 | 0.3 | 45 | 25 | 43.3 |

Phosphoric acid can be obtained from the direct reaction of ore with sulfuric acid; but a few minutes after starting the reaction, with the formation of calcium sulfate the reaction kinetics gets sorely slow and the dissolution efficiency decreases. Hence, in industrial producing phosphoric acid the circuit is designed in such a way a portion of the produced phosphoric acid is guided to the beginning of the line in order to dissolute the phosphate ore [12]. In this system, a great part of the fluorapatite reacts primarily with phosphoric acid, resulting in the production of soluble mono-calcium phosphate and hydrofluoric acid. Subsequently, high-efficiency phosphoric acid is produced by adding sulfuric acid with the specified molarity. The relevant reactions are as follows:

Ca10F2(PO4)6+14H3PO4→10Ca(H2PO4)2+2HF

10Ca(H2PO4)2+10H2SO4+20H2O→ 20H3PO4+10CaSO4.2H2O

Ca10F2(PO4)6+10H2SO4+20H2O→6H3PO4+10CaSO4.2H2O+2HF

In this section, the phosphoric acid, required for phosphate ore dissolution, was firstly obtained by sulfuric acid dissolution process. Although the dissolution efficiency was very low for the reasons mentioned in the previous sections, the above method was adopted to evaluate the feasibility of the design in industrial scale. Several tests according to Table 3 have been designed and performed to optimize the dissolution condition using sulfuric acid. Each experiment has been performed for 1 kg of phosphate ore. Selected levels for the dissolution parameters have been determined by performing several elementary rough tests.

| Experiment No | Sulfuric Acid Concentration (M) | Temperature (°C) | Time (min) | L/S Ratio | Dissolution Recovery (%) |

|---|---|---|---|---|---|

| 1 | 1 | 80 | 90 | 3 | 22.7 |

| 2 | 2 | 80 | 90 | 3 | 35.4 |

| 3 | 4 | 80 | 90 | 3 | 36 |

| 4 | 2 | 40 | 90 | 3 | 28.6 |

| 5 | 2 | 60 | 90 | 3 | 33.3 |

| 6 | 2 | 80 | 60 | 3 | 34.8 |

| 7 | 2 | 80 | 120 | 3 | 45.3 |

According to Table 3, the best dissolution efficiency has been obtained for 8th experiment with 2M acid concentration, 80°C temperature, 120 min time, and liquid to solid ratio of 4. Because there was no noticeable increase in dissolution efficiency with increasing acid concentration from 2 to 4 M, the 2 M concentration has been determined as optimized concentration. Other parameters have been optimized while this parameter was kept fixed. The obtained phosphoric acid included 47.5 g/liter P2O5.

In the next step, the ore firstly reacts with the previous section produced phosphoric acid to form soluble mono-calcium phosphate, and then by adding sulfuric acid to system according to the equations mentioned above, highefficiency phosphoric acid obtains. In all of the experiments the temperature and total time were fixed to 80°C and 180 min, respectively. The sulfuric acid has been added slowly 80 min after starting the reaction in all the experiments. The experiments results and conditions have been presented in Table 4.

| Experiment No | Sulfuric Acid Concentration (M) | L/S Ratio | Leaching Efficiency (%) |

|---|---|---|---|

| 1 | 1 | 3 | 65.1 |

| 2 | 1.5 | 3 | 72 |

| 3 | 2 | 3 | 78.9 |

| 4 | 2.5 | 3 | 83.6 |

| 5 | 3 | 3 | 84.5 |

| 6 | 3.5 | 3 | 84.5 |

| 7 | 2.5 | 4 | 88.7 |

Due to the fact that using high concentrations of sulfuric acid causes the digestion of other impurities in the environment [13], and the excess of this acid, as an impurity itself, must be removed from the system during purification, the 2.5 M concentration acid has been determined as optimized concentration which in the case of liquid to solid ratio of 4 resulted in the efficiency of 88.7%. The obtained phosphoric acid included 142.9 g/l P2O5. Then, in order to provide sufficient solution for purification experiments, a sample of 15 kg of soil has been dissolved using experiment number 7 (45.2 liters of solution was obtained). The following table shows the results of the analysis of this product (Table 5).

| Element | P2O5 | Iron | Sulfate | Mercury | Cadmium | Arsenic | Chloride | Florin |

|---|---|---|---|---|---|---|---|---|

| Concentration (mg/l) | 147500 | 1070 | 8500 | 15 | 32 | 55 | 1217 | 11200 |

Based on the impurities in the solution of produced phosphoric acid different processes have been applied to purify this solution in several steps. Firstly, a pre-purification step has been performed to remove humic acids using bentonite. Secondly, iron and fluorine have been removed using silica and sodium carbonate. Then, cadmium and arsenic were omitted by barium carbonate using excess sodium sulfide and sulfate ions [14-16].

Bentonite has been used to remove humic acids as well as some iron, so that 2 g of activated bentonite have been added for each 150 mL phosphoric acid and then stirred for 45 min. In the next step, 1.5 mL of flocculant (0.036 g flocculant in 250 mL water) has been added and then stirred for 30 min and finally filtered. The volatile acids in this product have been measured by titration to be 45 ppm.

Sodium carbonate and silica have been used to reduce the amount of iron and flour in the solution. 5.8 g silica and 10 g sodium carbonate have been added to 1 Liter phosphoric acid and the solution has been stirred in 70°C for an hour. Flour in the solution deposits as Na2SiF6 according to the following equation:

6HF+Na2CO3+SiO2→Na2SiF6+CO2+3H2O

On the course of reaction, a part of iron sediments in the form of ferrous as FeCO3. Sodium sulfide has been used to reduce the amounts of cadmium and arsenic in phosphoric acid. Therefore, 2 g sodium sulfide has been added to 2 Liters of phosphoric acid and then stirred for 60 min in the temperature of 55°C. The amount of arsenic has been decreased in this step. Then, the solution has been cooled to 30°C and 0.3 g sodium sulfide has been added and the solution has been stirred for 15 min to remove cadmium.

Barium carbonate has been used to reduce the amount of sulfate ion in phosphoric acid. Hence, 1 g of barium carbonate has been added to 1 Liter of phosphoric acid and then stirred for 60 min at the temperature of 55°C. The final phosphoric acid analysis is given in the Table 6.

| Element | P2O5 | Iron | Sulfate | Florin | Chloride | Arsenic | Lead | Cadmium | Mercury |

|---|---|---|---|---|---|---|---|---|---|

| Concentration (mg/l) | 148400 | 20 | 254 | 950 | 115 | 10 | 4 |

The suggested diagrams for the steps of washing, dissolving and purifying phosphoric acid are as follows (Figure 3):

Solvent extraction

Due to the importance of phosphoric acid purification, preliminary tests and optimization have been designed and implemented using DX7 software.19 experiments have been performed according to suggested design. The standardized effect of parameters has been presented in Figure 4. As it is observed, factor A (pH) has the greatest impact on experiments performed. After pH, the most effective factor is organic phase concentration (C). Both the A and C factors are directly related to the amount of recovery performed, and as each of the two factors increases, the extraction percentage also increases. The concentration of phosphoric acid in the Aqueous phase (D) is rated as the last influential parameter in this graph.

The variance analysis has been performed to determine the significance of each factor effect. As it can be seen in the Table 7, the presented model is a meaningful model with a probability of being accidentally less than 0.0001. The pH, organic phase concentration and aqueous phase concentration are known as valid factors. Because of the fact that the response obtained from the solvent extraction process is not linear, the curvature in the model is significant. It means that the variations in the percentage of extraction in different ranges of affecting factors are different. The probability of being accidental forfit-lackin residual factors is 11.24%, which indicates that the applied fitting is significant.

| Source | Sum of Squares | df | Mean Square | F Value | P-Value | |

|---|---|---|---|---|---|---|

| Prob>F | ||||||

| Model | 946.54 | 3 | 315.51 | 42.34 | 0.0001> | Significant |

| A-pH | 442.68 | 1 | 442.68 | 59.41 | 0.0001> | |

| C- Organic Phase Concentration | 353.06 | 1 | 353.06 | 47.38 | 0.0001> | |

| D- Aqueous Phase Concentration | 150.8 | 1 | 150.8 | 20.24 | 0.0001> | |

| Curvature | 93.8 | 1 | 93.8 | 12.59 | 0.0032 | Significant |

| Residue | 7.95 | 14 | 0.57 | |||

| Lack of fit | 6.11 | 11 | 0.56 | 0.91 | 0.01124 | Insignificant |

| Pure Error | 0.056 | 3 | 0.028 | |||

| Cor Total | 1144.66 | 18 |

As shown in Figure 3, the recovery increases with decreasing pH and aqueous phase concentration. The important point is that the contour diagram is not linear for the pH and aqueous phase concentration. When the second derivative of contour diagrams is zero, it indicates that there is no effective interaction between the two factors influencing process recovery. The presence of concatenation in Figure 5 is a justification for the presence of AD interaction.

In order to obtain the required number of steps for extraction operations in a continuous industrial circuit, 7 experiments with different ratios (1:1, 1:2, 1:3, 1:4, 4:1, 3:1, 2:1) were designed and performed based on the most optimal experiments. The extraction time was 10 minutes and the reaction temperature was adjusted on 45°C. The operating line is plotted for the O/A ratio of 1:1 and the result obtained by verticalizing the intersection point of the operating line and extending the initial concentration of the Aqueous phase, on the distribution curve of McCabe-Thiele diagram, indicates the need for two stages of extraction operations to transfer phosphoric acid from the aqueous phase to the organic phase (Figure 6). The sample obtained from solvent extraction process has been striped with the O/A ratio of 3.5 for 20 min using distilled water. The result of the sample analysis indicates the presence of 516.4 g/l P2O5 in the resulting solution along with a small amount of impurities mentioned in the Table 8 below.

| Element | P2O5 | Iron | Sulfate | Florin | Chloride | Arsenic | Lead | Cadmium | Mercury |

|---|---|---|---|---|---|---|---|---|---|

| Concentration (mg/l) | 516400 | 7 | 40 | 7 | 11 | <1 | 2 |

Fertilizers

In all the experiments in this section the Merck ammonium has been used for producing di-ammonium phosphate fertilizer. The chemical reaction associated with the production of di-ammonium phosphate is given as follow:

H3PO4 + 2NH3→(NH4)2HPO4

To select the most appropriate dissolution conditions and to know the constituents of the aqueous phase under the test conditions, pourbaix diagram (Eh-pH) for the phosphorus element has been plotted in acidic and alkaline environments and the temperature of 110°C, using HSC Chemistry 6 software. As it is obvious in the Figure 7, it is possible to form mono ammonium phosphate and diammonium phosphate in a wide range of electrochemical potentials. It is possible to find anion mono ammonium phosphate in the pH range of -1 to 7.4 and anion di ammonium phosphate in the pH range of 7.4 to 12.2. In the pH higher than 12.2 anion ammonium phosphate (or tri ammonium phosphate) can be formed. Based on the primary tests, it specified that it is possible to grow the crystals of these compounds only in a small range of pH. All experiments have been performed in a 500 cc Sealed beaker.

Di-ammonium phosphate

In order to optimize the production conditions of di-ammonium phosphate fertilizer, 27 experiments have been designed and performed using One Factor at a Time method. Three factors of time, pH and temperature have been investigated in three levels. These three levels have been determined based on literature, pourbaix diagram and primary rough tests. It is worth to note here some tests have been repeated two to three times for validation (Figure 8).

According to results of Table 9, the best result is related to the 17th experiment under conditions of 110°C for temperature, 60 min for time, and 8.5 for pH which resulted in producing 46.77% grade P2O5 with 95.78% efficiency. The crystals formed at the temperature of 110°C and pH=8.5 are in their largest state. The investigation for production of mono ammonium phosphate has been occurred as well and pure mono ammonium phosphate crystals obtained with the grade of 60.34% and the efficiency of 89.85%.

| Experiment No | pH | Temperature (°C) | Time (min) | P2O5 Recovery (%) | Product grade (%P2O5) |

|---|---|---|---|---|---|

| 1 | 8 | 90 | 45 | 27.43 | 34.24 |

| 2 | 8 | 90 | 60 | 27.43 | 34.24 |

| 3 | 8 | 90 | 75 | 27.89 | 33.74 |

| 4 | 8 | 100 | 45 | 46.21 | 36.65 |

| 5 | 8 | 100 | 60 | 45.11 | 37 |

| 6 | 8 | 100 | 75 | 45.11 | 37 |

| 7 | 8 | 110 | 45 | 57.58 | 38.95 |

| 8 | 8 | 110 | 60 | 56.27 | 39.48 |

| 9 | 8 | 110 | 75 | 59.64 | 40.23 |

| 10 | 8.5 | 90 | 45 | 79.88 | 41.29 |

| 11 | 8.5 | 90 | 60 | 81.56 | 41.58 |

| 12 | 8.5 | 90 | 75 | 80.24 | 41.44 |

| 13 | 8.5 | 100 | 45 | 86.61 | 43.32 |

| 14 | 8.5 | 100 | 60 | 86.08 | 42.12 |

| 15 | 8.5 | 100 | 75 | 86.22 | 43.16 |

| 16 | 8.5 | 110 | 45 | 93.26 | 44.75 |

| 17 | 8.5 | 110 | 60 | 95.78 | 46.77 |

| 18 | 8.5 | 110 | 75 | 94.56 | 45.18 |

| 19 | 9 | 90 | 45 | 74.97 | 40.55 |

| 20 | 9 | 90 | 60 | 76.58 | 40.14 |

| 21 | 9 | 90 | 75 | 76.58 | 41.67 |

| 22 | 9 | 100 | 45 | 79.26 | 43.19 |

| 23 | 9 | 100 | 60 | 82.39 | 43.58 |

| 24 | 9 | 100 | 75 | 83.25 | 43.78 |

| 25 | 9 | 110 | 45 | 94.63 | 42.12 |

| 26 | 9 | 110 | 60 | 95.92 | 43.34 |

| 27 | 9 | 110 | 75 | 92.54 | 44.04 |

Phosphate ore characterization analysis indicated 32.32% of P2O5 along with some elements such as iron, calcium, magnesium, chlorine, fluorine, arsenic and lead in the deposit. In order to produce phosphoric acid and remove the impurities, many primary washing experiments, the ore dissolution in different ways and first-stage purification of phosphoric acid have been designed and performed. In the next stage a novel mixture of extractants with high efficiency has been applied for purification and concentration of phosphoric acid by solvent extraction system. Kerosene was used as a solvent in these experiments. In the next step, the obtained phosphoric acid has been converted to di-ammonium phosphate and mono ammonium phosphate with 95.78% and 89.85% efficiency respectively, using ammonia during optimization tests.

Journal of Environmental Analytical Chemistry received 1781 citations as per Google Scholar report