Research Article - (2021) Volume 11, Issue 6

Received: 13-May-2021

Published:

30-Jun-2021

, DOI: 10.37421/2165-784X.2021.11.396

Citation: Honarvar E, Bolhasani A, Karamian S, Hosseini S, et al. “Application of Electrocoagulation in Treatment of Spent Caustic from Olefin Plants.” Civil Environ Eng 11 (2021): 396.

Copyright: © 2021 Honarvar E, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

In this research the electrocoagulation method was implemented in order to study the treatment of the spent caustic effluent from an olefin plant. To optimize the process parameters, Taguchi method was used, and the optimal conditions were found for pH of 6, current density of 35 mA/cm2, and treatment time at 40 minutes. The experimental results show that the final efficiency in case of reducing the amount of COD is around 89% under optimum operating conditions and pH has the most significant impact on the process with contribution factor of 79.10%. According to results of XRD and XRF analysis, the sludge behavior is very similar to that of sodium sulfate that is important for its value chain. The study results showed that the electrocoagulation method could be used a complimentary facility to reduce the amount of COD of Spent Caustic from an Olefin Plant.

Spent caustic • Electrocoagulation • Ethylene plant • Wastewater treatment

SC: Spent Caustic • COD: Chemical Oxygen Demand • WAO: Wet Air Oxidation • AOP: Advance Oxidation Process • TOC: Total Organic Carbon • EC: Electrocoagulation • BOD: Biological Oxygen Demand • XRD: X-Ray Diffraction • XRF: X-Ray Fluorescence • S/N: Signal to Noise Ratio • SS: Sum of Square • DC: Current Density.

Spent caustic is a type of injurious liquid waste byproduct, generated from hydrocarbon washing for elimination of acid gases components from hydrocarbon streams in olefin plants and other petroleum refineries [1]. The US Resource Conservation and Recovery Act classified It as harmfully industrial waste [2]. In this regards, it requires special handling and disposal before being released for conventional treatment with respect to sustainability and water security. To conform to the standards of wastes in the receiving medium, several attempts were developed for spent caustic treatment. One practical treatment method is the use of the wet air oxidation (WAO) reactor [3,4]. In this process, the reaction condition is often up to 300°C and 200 bar which makes this process very expensive while due to the sever operating condition, safety is a major concern [5]. Another commonly industrial process established by some technology providers includes neutralization with acids followed by stripping [6]. This process consumes large amount of acids to quench caustic which in fact are not easy handling due to the polymer agglomeration, occasionally observed in degassing vessel. Furthermore, in olefin plants, composition of the liquid feedstock responsible for altering the pyrolysis reaction and the concentration of the sulfur compounds that consequently could contribute to the disturbance in controlling the chemical oxygen demand (COD) of the effluent from the caustic wash tower [7]. Incineration is another available choice for spent caustic treatment; however, despite being a reliable and efficient operation, the energy requirement remains a big problem in this process [8]. Other techniques were also used including but not limited to the biological treatment, crystallization, chemical oxidation and precipitation [5].

Considering the above, each method has its limitation due to their kinetics, effectiveness, cost, safety and secondary pollution [9,10]. However, interest in electrocoagulation (EC), that is the subject of this study, is growing as a promising alternative as it poses benefits that eliminate the weaknesses of the traditional methods [11]. In this regards, the EC process characterized by in-situ generation of coagulants with no helps of chemical additives which in turns prevents the generation of secondary pollutants. Simple equipment and easy operation, short treatment time and also the ability to remove very fine particles are among the other benefits of the EC technology [12]. Because of these advantages, electrocoagulation has been used for treatment of different types of wastewater from petroleum refineries [13] and other industries [11-15]. Among researchers, Hariz et al. [13] has investigated treatment of refinery spent caustic using the electrocoagulation technique. However, despite to the impressive amount of research on the application of the electrocoagulation for treatment of various types of wastewater, a few researchers have been done on treatment of spent caustic from petrochemical plants.

The main objective of the present study, therefore, is to introduce a new approach to increase the efficiency of spent caustic treatment from olefin plant by applying the electrocoagulation technique in series with existing neutralization and stripping facilities. In this regards, the evaluation was performed in one litter laboratory scale reactor while Minitab software and Taguchi method were used to design the experiments for determining the effects of PH, time, current density and distance between the electrodes on efficiency of the electrocoagulation process. The produced sludge was separate from the effluent, and the COD was measured to monitor the effectiveness of spent caustic treatment [16-18].

Samples for spent caustic were collected from the olefin plant in Jam Petrochemical Company that manufactures various products such as ethylene and propylene under the license of Technip. Average analysis of these samples is given in Table 1. As it is shown, this wastewater has a very high COD that makes it difficult to be treated by the biological methods that is usually placed after the initial neutralization and stripping facilities, outside of the olefin plants. The electrocoagulation technique, explained by Ville Kuokkanen [19], was used to treat effluent. In this regards, the experiments were carried in an electrochemical cell with total volume of 1000 ml. In each experiment, 500 ml of spent caustic was treated in the cell. Iron electrodes were chosen because of their lower price than other electrodes such as aluminum while it is also more effective than aluminum in reducing the COD of industrial wastewater [20]. The iron electrodes in the size of 8 cm long and 6 cm wide were dipped into 5 cm distance from the cell bottom and connected to an ammeter to provide the necessary current. Additionally, a magnetic stirrer was used to provide sufficient mixing. A schematic diagram of the experimental set-up is shown in Figure 1. Analysis of the COD contents was performed using spectrophotometer and in accordance with the ASTM standard method (D 1252).

| Items | Value |

|---|---|

| Density | 1080-1100 Kg/m3 |

| •COD | 30000 ppm |

| TOC | 6000 -20000 ppm |

| Soluble Oil | 500-1500 ppm |

| Sulfides | 5,000 to 35,000 mg/L |

| BOD | 5,000 to 50,000 mg/L |

| Water | 86.7% |

| NaHS | 0.62% |

| Na2SO4 | 0.26% |

| NaOH | 2.01% |

| Na2CO3 | 10.42% |

A schematic of the steps of the effluent treatment process is shown in Figure 2. In the first stage, Spent Caustic effluent was neutralized with sulfuric acid. The electrocoagulation process was performed on and then the formed clots were removed from the effluent by sedimentation. In the second stage, pH adjustment was performed with sulfuric acid and Sodium hydroxide, and then the second stage of electrical coagulation was performed. After the completion of the electrical coagulation process, the sludge formed was separated from the effluent.

Treatment of spent caustic effluent by the electric coagulation method depends on interaction of different parameters such as reaction time, pH, current density, and distance between electrodes. The optimization of the parameters which are effective on the coagulation performance using traditional techniques is a difficult task which consumes considerable time and cost. Therefore, Taguchi method [21] has been applied for guiding the choice of the experiments to be performed in an efficient way. The purpose of this method is to optimize the response by determining the optimal range of factors that affect the process and analyzing the relationship between these factors, while minimizing the number of experiments and, consequently, spending less cost and time. This is due to the fact that this optimization approach utilizes orthogonal arrays from experimental design theory to study a large number of variables with a small number of experiments [22]. In this study, the full factorial design with L18 orthogonal array of Taguchi has been applied and shown in Table 2.

| Parameters | Levels | ||||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | ||

| PH | A | 6 | 7.5 | 9 | 10.5 | 12 | 13.5 |

| Time (min) | B | 20 | 40 | 60 | - | - | - |

| Current density (mA/cm2) | C | 20 | 35 | 50 | - | - | - |

| Distance (cm) | D | 1 | 3 | 5 | - | - | - |

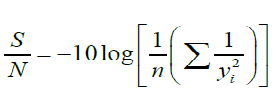

The signal to noise (S/N) ratio is an optimization standard in taguchi method so it was selected for parameters optimization. In this regards, the S/N ratio was calculated for COD with "the larger the better" case by the following equation where n is the number of repetitions for an experiment and y is the performance value of the ith experiment [23,24]:

(1)

(1)

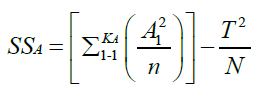

In order to conduct an analysis of the relative contribution of various parameters, an analysis of variance (ANOVA) was applied to the data. It indicates the effect of each investigated parameter on the optimization criterion. In ANOVA analysis, the values of sum of squares (ü) of individual parameter is calculated as follows:

(2)

(2)

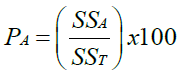

Here kA is the number of levels for parameter A, A1 is the sum of all observation of level 1 for parameter A, N is the number of all experiments and T is the sum of all observation. The percent of contribution of the individual parameters (PA) on the response is calculated as below where SST is the sum of squares for all parameters [25].

(3)

(3)

Electrocoagulation method was used for the first time for treatment of spent caustic effluent at olefin petrochemical unit. Optimal conditions for this process were adjusted for PH equal 6, the current density equal to 35, and residence time at 40 minutes. The pH parameter, with a share of 79.10%, has the greatest effect on the studied parameters. In these optimal conditions, the amount of sludge produced was 2 grams per half a liter of effluent or 4 kg per cubic meter of effluent. The removal efficiencies for optimal conditions were 89% for COD. The sludge produced in this process was sodium sulfate, which can be used in other industries. These results showed that the electrocoagulation method could be used as one of the efficient method individually or in combination with other treatment techniques for the spent caustic treatment in olefin plant.

Jam Petrochemical R&D team is working to do this process on a pilot scale in the future, for which we would like to thank them.

Journal of Civil and Environmental Engineering received 1798 citations as per Google Scholar report