Research Article - (2024) Volume 14, Issue 1

Received: 02-Oct-2023, Manuscript No. jcde-23-116385;

Editor assigned: 04-Oct-2023, Pre QC No. P-116385;

Reviewed: 18-Oct-2023, QC No. Q-116385;

Revised: 23-Oct-2023, Manuscript No. R-116385;

Published:

30-Oct-2023

, DOI: 10.37421/2165-784X.2023.13.518

Citation: Mission, Mark Paolo D. â??Detection of Construction Delays on Selected Residential Projects Located Near and Within Metro Manila During Actual Project Execution Using Contemporaneous Method of Measurement.â? J Civil Environ Eng 13 (2023): 518.

Copyright: © 2023 Mission MPD. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Construction delays are very common to the industry, and it is very evident in different kinds of construction projects. Even though there are construction guidelines, some companies still fail at some point in their overall cycle, and some consider these failures as norms. Such failures can have a significant impact on project performance. This research paper will analyze the effects of selected factors causing construction delays in residential projects. Contemporaneous method of measurement will determine the effect of each delay in labour hours of a 10-week construction period. The study will then determine the relation between some construction delay factors, and its overall effect in the construction progress. Then, the analysis will discuss the weaknesses of Contemporaneous Method of Measurement. The study will be conducted by means of actual observation data gathering and surveys on eight different residential projects with varying contractor/engineers. To evaluate the performance of the Contemporaneous Method of Measurement, the author will measure and collect the completion (in percentage) of accomplished activity on a daily to weekly basis, then, the gathered data will be compared to the planned accomplishment (actual over planned). For each delayed activity, the reasons will be stated why such delay occurred and what caused it basing from the selected factors of construction delays. The gathered data will then be analyzed with respect to time using linear regression for each type of delay and then applying a multiple regression for all of the types of delay on all the residential projects. The findings illustrate that Contemporaneous Method of Measurement is a reliable tool in defining the weak points of residential construction or which is most commonly called the project delays.

Construction delays • Residential projects • Contemporaneous

Construction is an activity that can be defined as a combined product of imagination, risk, detail- orientation, carefulness, safety, and analysis by means of architecture, cost and structural analysis, construction management, site execution and investigation. Another definition states construction as a broad process or mechanism for the realization of human settlements and the creation of infrastructure that supports development (Plescis2002, p.4). This includes maximizing of material utilization, manpower/labour distribution, project feasibility, return of income, learning from project difficulty and failure, operation and maintenance of the built environment/project, and most especially the cost and time which indicates a project’s success. The types of projects produced ranges from residential and non-residential to heavy constructions. According to Sunjka and Jacob 2013, construction is an industry process that is complex and dynamic, consisting of successful collaboration between several groups: the owners, contractors, local authorities, suppliers, professionals and others. Construction is vital to the nation’s economy since it provides access, improved standard of living, socio-economic growth, businesses and employments. A nation can be defined as either developing, developed, or underdeveloped based on the quantity and quality of completed construction projects.

The Philippines is considered as a developing country as plenty of constructed infrastructures are created along with high-rise residential buildings and housings, which is caused by the booming real estate industry. Construction project delays are considered a normal issue to most construction companies in different countries. In Nigeria, studies have been conducted that causes of delays in their country is assessed by means of focusing in actions and inactions of the contractors, the owners, consultants and some external factors. Some research studies have focused on the detailto- detail execution of construction, while some studies have focused on the internal relationships between participating groups in the project. There are many studies created to determine construction delays, residential or non – residential. In the Philippines there are not much data or local research papers that tackle on delays of construction projects, especially on the residential/ housing sector. There are plenty of international research studies created but not every method is applicable because of the construction industries’ complexity. Moreover, since delays are considered a part of every construction project, most parties consider it a norm depending on the magnitude of the delay, especially in residential projects wherein the length of construction time is less. Identification of delays is helpful but coordinative solutions may vary depending on the nature of the project [1].

Residential projects are in demand nowadays, along with the real estate industry, which is making a big impact on the global economy. Residential projects, in comparison to non-residential projects, create a distinction in terms of cost and operation. Residential/housing projects are easier to construct, and due to this, the planning for time to finish the project is not being focused on as compared to big projects. Big projects uses planning tools such as Critical Path Method (CPM) for means of defining the overall progress, while most residential/housing projects do not use such tools since the delays are quite lesser than those big projects. However, it is not conclusive that there are no delays or that delays are ignorable in the residential housing sector. Construction delays are very common in the industry; this comes in different aspects, by production control, mismanagement and lack of work force, poor execution of plans and resources, natural climates, and even late delivery of materials due to traffic. Contemporaneous method of measurement will gather information as to what percentage an activity is done even when delays are present. In addition, this system will determine specifically which factor is causing the delay [2].

The system will then give an idea to the participating engineers/contractors on what delays are occurring during or after the construction, measured in terms of time. Lastly, the realizations of the delays could serve as lessons to the participants so that they can avoid or work on such factors, and even create a further research on it. The function of this study to identify the causes of the delays, using the detailed data collected per span of measurement (daily to weekly basis). The data collected will be used for the comparison between the actual and the planned activity. Another data that will be gathered are the detailed project plan (labour distribution, weekly project goal/activity, material order and delivery, environmental factors, management approaches), and checking if the plans are accomplished or not. To clearly understand the problems created by delays and revisions on residential projects, the study will conduct actual investigations and surveys of eight residential projects of nearly the same scope of works so that the list of activities are of near variance. The performance of the study will then show its effectiveness in the workplace via management of plan execution to achieve performance goals. The study will determine how the project activities are planned and coordinated, what production goals are to be set, and how activities are released for execution. The system will also include changes in the execution itself, such as adjusting the work plans, providing necessary resources, and guaranteeing that actual execution will reach it targeted goals. Once every detail has been followed and worked on, this system will define what causes the delays and in what percentage does it affect the progress of the construction [3].

This paper will focus mainly on the residential construction, primarily because the performance provides results in terms construction delays and reworks and will show quick and evident results, and since residential construction is high in demand nowadays, it will be beneficial because it will be converted to an economical improvement. In addition, the area covered by the study will be limited to projects located near and within Metro Manila only so that the pricing of materials, sources of work force, and environmental incidents, will be of a near homogenous value. The study will demonstrate how such delays affect the time performance of residential project construction. Since the scope of works in residential projects are lower in compared to other construction projects, the chosen causes of delays will be measured in a timely manner. Unlike the CPM, Bar Chart, and S – Curve, wherein the measurement of delay is in terms of days lost in the as-planned schedule, this research study will provide a combined and concurrent effects of chosen specific delays in terms of time performance. The study is limited only to residential projects that range from 150 to 250 square meters. Chosen specific delays (environmental factors, policies and guidelines, labour/manpower, materials, prerequisite work, priority work, nature of activity) are the only parameters to be measured during actual site investigation, and these are based from industry practitioners and related literatures [4].

The study will focus on the effectiveness of a contemporaneous method of delay measurement in eight different residential projects, ranging from 150 to 200 square meters, for the reason that the list of weekly activities are of the same range and sequence, based on all of the projects’ list of weekly works, construction experience of the researcher, and surveys from co-engineers who are on the field of residential construction. All of which is to be located near and within Metro Manila for the homogeneity of the values (pricing of materials, source of manpower, characteristics of manpower, and environment) will be of a close value. The goals to be set are the following:

• Classify each causes of delay and its correlation with project success

• Identify the relationships of delays to each other

• Actual checking of the activities and evaluate its actual progress vs. the planned progress (As Built vs. As Planned)

• Record the reasons for the cause of delay

• Plot and analyze the causes and percentage of delay vs. time individually per project and per cause of delay

• Analyze using linear regression (correlation, R and R2 values) for every cause of delay per project

• Significance testing of all the projects and causes of delays using multiple regression (scatter plot), wherein the delays are the independent variables and the dependent variable is time in manhours

• Analyze and understand why the method failed and determine the factor(s) that caused the failure

• Develop the sets of lessons learned from the failure for the improvement of project performance

Data to be gathered on actual site observation

Natural weather/environmental factors: Severe weather conditions affect most parts of construction process. Examples of natural weather conditions and environmental factors are heavy rainfall, earthquakes, floods, tsunami (if near coast), and fire. These are uncontrollable and unforeseeable circumstances and categorized as acts of God. Natural weather is a huge indicator of delay since it has an effect on all other delay factors (example: if it rains hard, some labourers cannot go to work, or the delivery of cement and concrete will be delayed because it might get wet). For the data gathering, the number of hours this factor (i.e. rainfall) occurred will be measured, and will be compared and computed to the supposed number of hours of activity for that day [5,6].

Materials

Materials as a cause of delay are described in several ways:

• Availability/Unavailability of materials

• Delivery of material (time of delivery, quantity delivered, completeness of the delivery)

• Quality of material to be used

• Source of material

• Delivery conditions

• Planned order of delivery

Materials, on basic construction knowledge, can really cause a delay especially if the supposed activity is to be done but there is unavailability of materials. For the data gathering, availability of the material based on the need for the day’s activity will be measured in percentage (ex.: late delivery of gravel and sand before pouring the ground floor slab).

Manpower/labour:

• Quantity Distributed

• Availability

Labour is a known factor of delay because this describes the work to be done (carpentry, masonry, steel works, and helper). Distribution of labour are prone to delays especially if there is not enough manpower to do the activities, also, even if there are enough manpower but the distribution is mismanaged, possible delays could occur because the list of activities in construction is complex. F or the data gathering, characteristics of the labour will be neglected (age, education, capacity, skill sets) because this is a broad topic to analyze, thus this may lead to error if analyzed [7].

Nature of activity: This is considered a factor of delay because the complexity of construction itself requires different approaches. Nature of activities (excavation, hauling, grubbing, clearing, preparation of formworks for beams and slabs, concreting of slabs, beams and columns, fabrication and bending of steel reinforcements, etc.), especially when there are lack of equipment to be used, or when it is not planned ahead, will cause delay.

Prerequisite work: These are the list of activities that were not completed during its supposed date of completion. Prerequisite work, is the day-to-day, weekly, or even monthly (in big projects) sequence of activities.

Priority work: Changing of priority of work during actual construction may lead to advantages like early completion, but often, changing of priority is being done because some previous work were not completed, or an unplanned activity is observed, thus, focusing on the prioritized work and disregarding the as-planned schedule and affecting the activity that is supposed to be worked on.

Assumed percent completion of daily activity based on basic construction knowledge: The researcher must be familiar in the percentage estimate of how the project was completed. He may ask the engineers on site and evaluate if their assumptions meet.

Planned schedules per week: This is the as-planned schedule before the actual construction. However, since most of the process and practices of residential construction in the Philippines does not require and provide a real as-planned schedule, the data gathering for this factor will be based on the knowledge or procedure of the engineer itself basing from his experience and management [8].

Actual accomplishment: This is similar to the as-built schedule in a common construction practice. Since there will be no as-planned schedule, the actual accomplishment will be based on the researcher’s unbiased evaluation along with the evaluation of the engineer of the project. Information/reasons for the cause of delays: This is the evaluation on how and why delay happened and its effect on the project accomplishment. The evaluation should reflect the work of the labourers, materials, and external factors.

Comparison of accomplishment (Actual vs. planned): A rubric (site questionnaire or evaluation form) will be given to the engineers per project. The researcher will describe and discuss to the engineer on how to answer and provide information the rubric, this is to prevent or lessen the errors that could be made (such as wrong input and assumptions). After gathering all of the data needed, percent plan completion (in percentage) will be recorded in a table to describe the production control system. If the completion percentage for that week’s activity were less than 100%, it would simply describe that the activity for that specific week has experienced project delays and by using the rubrics, the causes of the delays can be detected. To describe the relationship of the delays vs. the factors that are causing it, multiple regression analysis is the statistical method to be used. It is a model that would analyze the relationship between a dependent variable (delay/time) and one or more independent variables (causes of delays). If the model would show misleading results, the action to be done is to do more sampling (add more residential projects for the study).

Respondents of the study: The samples to be surveyed in this study are residential projects located near or within Metro Manila. Projects of Engr. Leon Gonzales, Engr. Dave Jovi Sardua, Engr. Rogie Kolimlim, and Engr. Felix Borja were selected since the categories of their projects are fit for the study. Listed in the appendices are the project details.

Data gathering procedures: For every residential project, a rubric (evaluation form) is going be given to the engineers. For every site they handle, they will provide the amount of accomplishment (daily), with respect to their estimated list of activity for the said date. The gathering of data will begin from the project start, on an 8-hour basis (8am – 5pm), and they will indicate the reason on how such delay occurred. Then, the amount of percent delay will be multiplied to 8 hours so that it could be converted into time performance. The sample rubric is shown on the succeeding page (Table 1).

| Factor (Example Environmental) | Average | Activity | Notes - Remarks | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Unit Number | |||||||||

| Week 1 | |||||||||

| Day | 1 | 2 | 3 | 4 | 5 | 6 | Example: Clearing and Grubbing, Site Layout, Markings | Example: Not much delay, it only rained on Tuesday | |

| Date | 01-04-17 | 01-05-17 | 01-06-17 | 01-09-17 | 01-10-17 | 01-11-17 | |||

| %Accomplishment | 100% | 63% | 100% | 100% | 75% | 75% | |||

| %Planned | 100% | 100% | 100% | 100% | 100% | 100% | |||

| %Acc - % Planned | 100% | 63% | 100% | 100% | 75% | 75% | 86% | ||

| Total Hours Worked | 8 | 5.04 | 8 | 8 | 6 | 6 | 41.04 | ||

| Week 2 | |||||||||

| Day | 1 | 2 | 3 | 4 | 5 | 6 | Example: Excavation, Preparation of Barracks, Mobilization, Concreting of Septic Tanks | Example: No rainfall from Monday to Wednesday, Rains from Thursday to Saturday affected excavation works | |

| Date | 01-12-17 | 1-13-17 | 1-14-17 | 1-16-17 | 1-17-17 | 1-18-17 | |||

| %Accomplishment | 100% | 100% | 100% | 70% | 90% | 90% | |||

| %Planned | 100% | 100% | 100% | 100% | 100% | 100% | |||

| %Acc - % Planned | 100% | 100% | 100% | 70% | 90% | 90% | 92% | ||

| Total Hours Worked | 8 | 8 | 8 | 5.6 | 7.2 | 7.2 | 44 | ||

| Week 3 | |||||||||

| Day | 1 | 2 | 3 | 4 | 5 | 6 | Example: Fabrication of rebars and formworks | Example: Heavy rainfall on Thursday, caused 4 hours of rains | |

| Date | 1-19-17 | 1-20-17 | 1-21-17 | 1-23-17 | 1-24-17 | 1-25-17 | |||

| %Accomplishment | 100% | 100% | 100% | 50% | 88% | 75% | |||

| %Planned | 100% | 100% | 100% | 100% | 100% | 100% | |||

| %Acc - % Planned | 100% | 100% | 100% | 50% | 88% | 75% | 86% | ||

| Total Hours Worked | 8 | 8 | 8 | 4 | 7.04 | 6 | 41.04 | ||

| Week 4 | |||||||||

| Day | 1 | 2 | 3 | 4 | 5 | 6 | Example: Concreting of foundations and backfilling | Example:scatered rainfall but not much effect; Saturday rains caused 4 hours delay | |

| Date | 1-26-17 | 1-27-17 | 1-28-17 | 1-30-17 | 1-31-17 | 02-01-17 | |||

| %Accomplishment | 88% | 100% | 100% | 100% | 88% | 50% | |||

| %Planned | 100% | 100% | 100% | 100% | 100% | 100% | |||

| %Acc - % Planned | 88% | 100% | 100% | 100% | 88% | 50% | 88% | ||

| Total Hours Worked | 7.04 | 8 | 8 | 8 | 7.04 | 4 | 42.08 | ||

| Week 5 | |||||||||

| Day | 1 | 2 | 3 | 4 | 5 | 6 | Example: Fabrication of rebars and formworks for slab - aligning of wastewater line, water line, electricaal line, preaparation of tie beams for columns | Example: rains a lot during the week, much works are affected | |

| Date | 02-02-17 | 02-03-17 | 02-04-17 | 02-06-17 | 02-07-17 | 02-08-17 | |||

| %Accomplishment | 50% | 75% | 100% | 88% | 90% | 100% | |||

| %Planned | 100% | 100% | 100% | 100% | 100% | 100% | |||

| %Acc - % Planned | 50% | 75% | 100% | 88% | 90% | 100% | 84% | ||

| Total Hours Worked | 4 | 6 | 8 | 7.04 | 7.2 | 8 | 40.24 | ||

| Week 6 | |||||||||

| Day | 1 | 2 | 3 | 4 | 5 | 6 | Example: Concreting of column from 1st to L-4, abang ng biga | Example: not much rainfall, works have preceeded | |

| Date | 02-09-17 | 02-10-17 | 02-11-17 | 2-13-17 | 2-14-17 | 2-15-17 | |||

| %Accomplishment | 88% | 100% | 100% | 100% | 100% | 100% | |||

| %Planned | 100% | 100% | 100% | 100% | 100% | 100% | |||

| %Acc - % Planned | 88% | 100% | 100% | 100% | 100% | 100% | 98% | ||

| Total Hours Worked | 7.04 | 8 | 8 | 8 | 8 | 8 | 47.04 | ||

| Week 7 | |||||||||

| Day | 1 | 2 | 3 | 4 | 5 | 6 | Example: slab of 2nd flr - trusses | Example: 4 hours rainfall on wedneday, concreting of slab was delayed | |

| Date | 2-16-17 | 2-17-17 | 2-18-17 | 2-20-17 | 2-21-17 | 2-22-17 | |||

| %Accomplishment | 100% | 75% | 50% | 100% | 100% | 100% | |||

| %Planned | 100% | 100% | 100% | 100% | 100% | 100% | |||

| %Acc - % Planned | 100% | 75% | 50% | 100% | 100% | 100% | 88% | ||

| Total Hours Worked | 8 | 6 | 4 | 8 | 8 | 8 | 42 | ||

| Week 8 | |||||||||

| Day | 1 | 2 | 3 | 4 | 5 | 6 | Example: concreting of beams and columns up to roof beams | Example: Sunny the whole week; work was not affected | |

| Date | 2-23-17 | 2-24-17 | 2-25-17 | 2-27-17 | 2-28-17 | 03-01-17 | |||

| %Accomplishment | 100% | 100% | 100% | 100% | 100% | 100% | |||

| %Planned | 100% | 100% | 100% | 100% | 100% | 100% | |||

| %Acc - % Planned | 100% | 100% | 100% | 100% | 100% | 100% | 100% | ||

| Total Hours Worked | 8 | 8 | 8 | 8 | 8 | 8 | 48 | ||

| Week 9 | |||||||||

| Day | 1 | 2 | 3 | 4 | 5 | 6 | Example: Roofing - finishing | Example: Heavy rainfall on Wednesday. Roofing works was delayed for 6 hours | |

| Date | 03-02-17 | 03-03-17 | 03-04-17 | 03-06-17 | 03-07-17 | 03-08-17 | |||

| %Accomplishment | 75% | 100% | 38% | 80% | 100% | 100% | |||

| %Planned | 100% | 100% | 100% | 100% | 100% | 100% | |||

| %Acc - % Planned | 75% | 100% | 38% | 80% | 100% | 100% | 82% | ||

| Total Hours Worked | 6 | 8 | 3.04 | 6.4 | 8 | 8 | 39.44 | ||

| Week 10 | |||||||||

| Day | 1 | 2 | 3 | 4 | 5 | 6 | Example: Finishing- Investigation | Example: No much rainfall, finishing works are not much affected | |

| Date | 03-09-17 | 03-10-17 | 03-11-17 | 3-13-17 | 3-14-17 | 3-15-17 | |||

| %Accomplishment | 100% | 100% | 100% | 100% | 100% | 88% | |||

| %Planned | 100% | 100% | 100% | 100% | 100% | 100% | |||

| %Acc - % Planned | 100% | 100% | 100% | 100% | 100% | 88% | 98% | ||

| Total Hours Worked | 8 | 8 | 8 | 8 | 8 | 7.04 | 47.04 | ||

| Total Average: | 90% | ||||||||

| Total Hours: | 431.92 | ||||||||

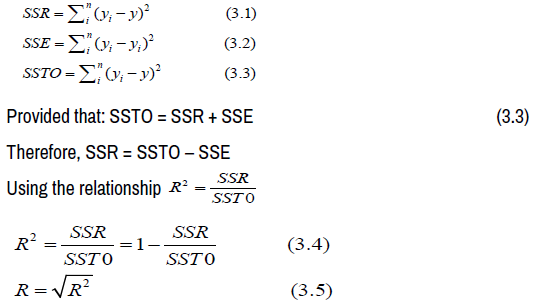

Statistical treatment: Linear regression will be used to prove the significance of each delay with respect to time. The correlation data (R) will be measured to determine if there will be a direct relationship between a factor and time. The value of R2 will show its percentage of variation. A higher value or R and R2 will mean greater correlation and relationship with time. Once the factors have been proven to be related, multiple regression using scatter plots will be used to verify the overall relationship between the independent variables (delay) and dependent variable (time). The determination of R, R2, Standard Error of Estimate, and other factors are solved using the following formulas:

SSR is the regression sum of squares. It quantifies how far the estimated

sloped regression line, ŷi, is from the horizontal "no relationship line," the

sample mean or

• SSE is the error sum of squares. It quantifies how much the data points, yi, vary around the estimated regression line, ŷi.

• SSTO is the total sum of squares. It quantifies how much the data points, yi, vary around their mean, ȳ.

• R is the correlation, of a dependent factor

• R2 is the coefficient of determination, or the regression sum of squares divided by the total sum of squares. Its limits must only be from zero to one. Zero value means that the plot is a horizontal line, or no correlation between the dependent variables and the independent variable. Value of one means that the slope is a perfect fit, which means that all dependent variables are 100% correlated with the independent variable [9,10].

The data and expected results shall be created using SPSS (Statistical Package for the Social Sciences). After the determination of the results, the plotting of the multiple linear regression line will be of a manner shown below (Figures 1 and 2).

The equation y = β0 + β1x will be the true regression (fit) line, which means that the points directly falling on this sloping line is 100% correlated with the independent variable y. However, since the expected results will be plotted on a scattered manner, there will be some variance on most of the data that will be gathered. Therefore, the model equation will have to be y = β0 + β1x +ɛ, wherein ɛ is the random deviation or random error. Without ɛ, any observed pair (x, y) would be plotted directly on the true fit line. The inclusion of ɛ allows the (x,y) values to fall either above (ɛ>0) or under (ɛ<0) the true fit line (Figure 3).

The results shown below indicate the correlation of each factor with time, wherein the factors are the independent variables and time (in man-hours) is the dependent variable. The results were gathered using SPSS.

Correlation and regression between time and environmental factors

The time and environmental factors are directly related. Using correlation (R), it can be seen that there is a high association/relationship between the time and environmental factors. With correlation coefficient of 0.883, time is positively correlated to the environmental factors. Almost 78% of the variability observed in the time can be explained by the environmental factors (Tables 2 and 3).

| Model | R | R Square | Adjusted R Square | Std. Error of the Estimate |

|---|---|---|---|---|

| 1 | .883a | .779 | .742 | 5.032 |

| Model | Unstandardized Coefficients | Standardized Coefficients | t | Sig. | |

|---|---|---|---|---|---|

| B | Std. Error | Beta | |||

| 1 (Constant) Environmental Factors |

159.092 | 60.733 | .883 | 2.620 | .040 |

| 296.715 | 64.496 | 4.601 | .004 | ||

Correlation and regression between time and policy and guidelines

The time and policy/guidelines are directly related. Using correlation (R), it can be seen that there is a high association/relationship between the time and policy/guidelines. With correlation coefficient of 0.837, time is positively correlated to the policy/guidelines. 70% of the variability observed in the time can be explained by the policy/guidelines (Tables 3 and 4).

| Model | R | R Square | Adjusted R Square | Std. Error of the Estimate |

|---|---|---|---|---|

| 1 | .837a | .0.7 | .0.65 | 5.866 |

Correlation and regression between time and materials

The time and materials are directly related. Using correlation (R), it can be seen that there is a moderate association/relationship between the time and materials. With correlation coefficient of 0.507, time is positively correlated to the materials. Almost 26% of the variability observed in the time can be explained by the materials (Tables 5 and 6).

| Model | Unstandardized Coefficients | Standardized Coefficients | T | sig. | |

|---|---|---|---|---|---|

| B | Std. Error | Beta | |||

| 1.(Constant) Policy/Guideline s |

67.722 | 99.117 | .837 | .683 | .520 |

| 388.627 | 103.901 | 3.740 | .010 | ||

| Model | Unstandardized Coefficients | Standardized Coefficients | T | sig. | |

|---|---|---|---|---|---|

| B | Std. Error | Beta | |||

| 1.(Constant) Materials |

286.074 | 105.843 | 0.507 | 2.703 | 0.035 |

| 167.594 | 116.416 | 1.44 | 0.2 | ||

Correlation and regression between time and labour/ manpower

The time and labour/manpower are directly related. However, using correlation (R), it can be seen that there is a very low association/relationship between the time and labour/manpower since it is closer to zero; which can be considered has no relationship at all. With correlation coefficient of 0.106, time is positively correlated to the labour/manpower. It is almost zero variability observed in the time can be explained by the labour/manpower since its value is 0.011 or 1.1%. (This maybe is affected by some variables such as materials) (Tables 7 and 8)

| Model | R | R Square | Adjusted R Square | Std. Error of the Estimate |

|---|---|---|---|---|

| 1 | .106a | .011 | -.153 | 10.647 |

| Model | Unstandardized Coefficients | Standardized Coefficients | T | sig. | |

|---|---|---|---|---|---|

| B | Std. Error | Beta | |||

| 1.(Constant) Labour/Manpower |

366.815 | 273.127 | .106 | 1.343 | .228 |

| 75.926 | 289.762 | .262 | .802 | ||

Correlation and regression between time and pre-requisite work

The time and pre-requisite work are directly related. Using correlation (R), it can be seen that there is a high association/relationship between the time and pre-requisite work. With correlation coefficient of 0.945, time is positively correlated to the pre-requisite work. 89.3% of the variability observed in the time can be explained by the pre-requisite work (Tables 9 and 10).

| Model | R | R Square | Adjusted R Square | Std. Error of the Estimate |

|---|---|---|---|---|

| 1 | .945a | .893 | .876 | 3.496 |

| Model | Unstandardized Coefficients | Standardized Coefficients | t | sig. | |

|---|---|---|---|---|---|

| B | Std.Error | Beta | |||

| 1.(Constant) Pre-requisite Work |

233.522 | 28.912 | .945 | 8.077 | .000 |

| 230.172 | 32.456 | 7.092 | .000 | ||

Correlation and regression between time and priority work

The time and priority work are directly related. Using correlation (R), it can be seen that there is a high association/relationship between the time and priority work. With correlation coefficient of 0.937, time is positively correlated to the priority work. 87.8% of the variability observed in the time can be explained by the priority work (Tables 11 and 12).

| Model | R | R Square | Adjusted R Square | Std. Error of the Estimate |

|---|---|---|---|---|

| 1 | .937a | .878 | .858 | 3.739 |

| Model | Unstandardized Coefficients | Standardized Coefficients | t | sig. | |

|---|---|---|---|---|---|

| B | Std. Error | Beta | |||

| 1.(Constant) Priority Work |

232.074 | 31.418 | .937 | 7.387 | .000 |

| 238.843 | 36.342 | 6.572 | .001 | ||

Correlation and regression between time and nature of activity

The time and nature of activity are directly related. However, using correlation (R), it can be seen that there is a high association/relationship between the time and nature of activity. With correlation coefficient of 0.840, time is positively correlated to the nature of activity. Thus, 70.7% variability observed in the time can be explained by the nature of activity. The figure above shows the uphill pattern as you move from left to right, which indicates a positive relationship between the factors causing delay (environmental, policy/ guidelines, materials, labour/manpower, pre-requisite work, priority work, and nature of activity) and the time to accomplish the project. This means that as the factors causing delay increases, the time to accomplish the project also increases. Moreover, if the factors of causing delay decreases, the time to accomplish also decreases. If the data show an uphill pattern as you move from left to right, this indicates a positive relationship between X and Y. As the X-values increase (move right), the Y-values tend to increase (move up) (Tables 13 and 14, Figure 4).

| Model | R | R Square | Adjusted R Square | Std. Error of the Estimate |

|---|---|---|---|---|

| 1 | .840a | .705 | .656 | 5.815 |

| Model | Unstandardized Coefficients | Standardized Coefficients | t | sig. | |

|---|---|---|---|---|---|

| B | Std. Error | Beta | |||

| 1.(Constant) Nature of Activity |

182.513 | 67.591 | .840 | 2.700 | .036 |

| 277.734 | 73.334 | 3.787 | .009 | ||

Construction delays are very evident in the industry, either in residential or non- residential projects. In residential projects, it is a norm that the projects are not provided with an actual schedule to follow, meaning that the process of the construction can be done by simply relying on the engineer’s knowledge. In this study, the researcher was able to conclude that the chosen several factors are considered a contributor to the delays being experienced of a project. Eight residential projects were selected with characteristics that are almost the same (two-storey, ranging from 150-200 sq. m floor area), to gather a near or homogenous results. Sequentially, the chosen delays are ranked as follows (from highest to lowest contribution):

• Pre – Requisite Work (R2= 89.3%)

• Priority Work (R2= 87.8%)

• Environmental Factors (R2= 78%)

• Nature of Activity (R2= 70.5%)

• Policy and Guidelines (R2= 70%)

• Materials (R2= 25.7%)

• Labour/Manpower (R2= 1.11%)

Pre-requisite work as a chosen factor of delay creates a very big contribution to the overall delay of the project. These delays are the works left unfinished from a previous scope of work, such examples are when the supposed schedule should be concreting of second floor slab, but then the actual activity is just yet the concreting of the columns in the ground floor, and some similar and related incidents. Priority work, on the other hand, is the mere changing and switching of activities due to the unforeseen incidents and delays. It is closely related to the pre-requisite work. For is the environmental factors, these are mostly focused on days wherein rainfall occurred. Nature of activity such as special requests (hauling of garbage, village homeowner’s requests, etc.) also caused delays because it is taking off time in the construction project. While for the policy and guidelines, these are all mandatory regulations, from local to national government. Such examples are the truck ban from 6:00 am to 10:00, which greatly affects the delivery of materials for the project. Materials, meanwhile, creates a low contribution as compared to the first chosen factors of delays. It creates a 25.7%, which is a low correlation yet it still poses contribution to the project delays. Examples of material as a cause of delays are when a material has been bought incorrectly, defect on material is observed, and if the quantity of the material bought, is insufficient. Lastly, for the labour/manpower as a source of delay, it caused an unexpected percentage of delay as 1.11%, which has the least and lowest correlation. Since residential construction is not as extensive as compared to big infrastructures, the labour distribution of works is quite easy because the scope of work is less. Thus, it is notable that labour can only cause delays if the foreman/engineer handling the manpower distribution is inexperienced and inefficient.

Overall, construction delays are described by different factors, and as mentioned in the related literature, it can be shown in different aspects. For this study, the chosen factors of delay projected a relationship with varying results. Residential projects, however, posed almost the same projection to bigger construction projects aside from the material and labour aspects. It is thus conclusive to say that small projects with fewer items quantifiable (labour distribution, portion of materials) create little or no relationship with time. Since residential projects are done in a manner of irregular basis, labour distribution can be managed simply without the assistance of an experienced engineer. While factors that are highly quantifiable such as number of unfinished works, hours lost due to weather and legislations create a big relationship with time. Although the measurements made on this study may still vary with other projects, this paper can still be of a good reference to engineers and future researchers as they can avoid delays or focus on the factor that may cause it. Measurement of delays can be quite difficult; however, the avoidance to a predicted root of problem before it occurs can mean an early success to a project.

Journal of Civil and Environmental Engineering received 1798 citations as per Google Scholar report