Research - (2020) Volume 11, Issue 6

Received: 03-Dec-2020

Published:

24-Dec-2020

, DOI: 10.37421/2151-6219.2021.11.344

Citation: Abdelrhman, Hamdon A. "Development of Financial Mode and Environmental Value of Roselle (Hibiscus sabdariffa) for Producing Natural Fiber Utilization into Technical Textile." Bus Eco J 11 (2020) : 344

Copyright: © 2020 Abdelrhman HA. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits

unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

The objectives of this research are to develop a financial model of roselle fiber utilized into technical textile, as well as estimation of carbon emission and storage of its fiber utilization into Technical textile. The data were collected through the focus group discussion with roselle growers as well as the sellers. To supplement the primary data, the secondary data were used; the surrogate market mechanism also was applied. The cost benefit analysis model was developed. The results depicted that, the roselle fibers utilized into technical textile with aramid replacement by 30% financially is feasible with high NPV, ROI, IRR and BCR exceeding one. Moreover, varying the discount rate from 8% to 15% raising the price of clean bast fiber prices by 20% raising the cost of investment by 20%, the analysis illustrated that, roselle fiber is financially viable in all the suggested sensitivity analysis. The result of the investigation proposed a financial model can be used for commercialization of roselle plant and its fiber products. Also the study concluded that, the initiation of roselle fiber market is highly recommended and utilization of its fibers in industrial products is very crucial to help the farmers for generating additional income by using the fiber and diversify the products of the roselle crop. Also, the study concluded that, research in roselle core and bast usage in industrial applications is highly needed, also, the study concluded that, the assessment of environmental impact of roselle cultivation and fiber utilization is highly recommended.

Industrial product • Carbon emission • Technical textile • Industrial products • Roselle fiber

At present, there are very scarce studies have been conducted on the application of roselle fibers as industrial product [1]. To date, studies are still being performed on the properties of roselle fibers and their capability to replaced synthetic fibers in engineering applications. Based on this review, the authors have identified that the feasibility studies that have been conducted on this highly potential plant have only covered the mechanical properties and dimensional stability of these composites and the effect of surface treatment [1].

Sudan karkadeh as African fiber belongs to the bast fiber group. Their properties are similar to kenaf and jute, which are already established in many manufactured products such as composite [2]. According to [2], roselle fiber has the same characteristic of kenaf and jute which have been extensively used in the automotive industry, especially in the production of automotive parts [3,4]. In addition, kenaf and other natural fibers have been used in construction and aerospace applications due to their reliability as reinforced materials [5]. Therefore, the author strongly believes that roselle fiber can also be applied in automotive parts and accessories and biomedical and aerospace industries because the properties are comparable to those of other established bast fibers such as kenaf and jute [1].

Roselle (Hibiscus sabdariffa L.) Hibiscus sabdariffa L belongs to family Malvaceae, generally known as roselle or red sorrel in English and in Arabic called karkadeh, is widely grown in Central and West Africa, South East Asia, and western Sudan (Mohamed, et al, 2012). In addition, the roselle might have been domesticated as many centuries ago in Sudan. Hibiscus section Furacaria (Malvaceae), to which Roselle belongs, is a morphologically contains natural group of more than 100 known species. This group includes a number of fibre, food, and medicinal plants such as kenaf (H. cannabinus) and roselle (H. sabdariffa). Depending the place of roselle grown, it is an annual or perennial herbaceous shrub. The thick, red and fleshy, cup-shaped calyces of the flower are used worldwide as a cold beverage and as a hot drink).These extracts are also used in folk medicine against many diseases which include high blood pressure, liver diseases and fever.

The red anthocyanin pigments in the calyces are used as food colouring agents. The swollen calyces are the part of the plant of commercial benefit [6-11]. Stated that, Roselle calyces are the major product used for beverages and commercially available to provide an extracts which can be used in the food colouring and pharmaceutical industries for health benefits.

Financial assessment of roselle cultivation for producing fiber

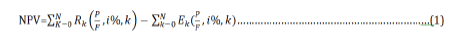

Cost and Benefit Analysis (CBA): In this objective the financial cost and benefit analysis which rely on net present value (NPV) and benefit cost ratio (BCR) were applied to estimate the profitability of roselle production by measuring the following components:

The total initial cost invested in roselle fiber production and utilization, this amount includes the cost of the labor, materials, land and machinery. The profitability of roselle fiber production and utilization into the technical textile calculated by using a time frame of 10 years. The formula used for CBA is as follows:

Where Rk is the revenues for k years, Ek is expenses for k years, i % is the discount rate and P/F is the discount factor used. If the Net Present Value positive, then one should proceed with it; if it is negative, one should note as this indicates that the business management is inefficient so the government should take the decision to pursue manufacturing of the product. To review the overall performance of operations, Net Present Value (NPV) is computed in this study. The annual income and returns are estimated for ten years and then discounted to present values. The total discounted revenues and costs show whether the business earns more benefits or costs. If NPV is positive, the business will potentially create a net return (profit) to the investor. On top of that, the NPV's magnitude indicates the expected benefit of the business.

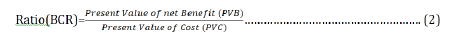

Benefit-Cost Ratio (BCR): Benefit-Cost Ratio (BCR) is to estimate the benefit received per unit cost of the project. It is thus an indicator of the efficiency of project investment. If BCR value is greater than 1, the business is justified taking into account economic grounds and the higher the BCR value, the higher the effectiveness of this business. Followed the equation of BCR, the estimated financial values for each of the criteria with costs and benefits being calculated over a period of 10 years. All the costs and benefits has been discounted at discount rate of 10%.

Benefit to Cost

Internal Rate of Return (IRR): Before we find the NPV, we have to discover first the discounted sum of total revenue and discounted sum of total cost using the interest rate of 10% which both of them known as the present value of benefit and the present value of cost.

Downstream processing and manufacturing of roselle fiber

At this stage of the reporting an attempt is made to draft a cashflow of a technical textile factory using roselle fiber. This could represent a potential investment opportunity in the utilization of clean bast roselle fibers to replace 30% of aramid fiber requirements in the making of technical texstile.

A sensitivity analysis

A sensitivity analysis has to be undertaken to determine how robust the financial analysis results under adverse conditions such as are

1. Varying the discount rate from 10% to 15%

2. Raising the price of clean bast fiber prices by 20%

3. Raising the cost of investment by 20%.

The estimation of carbon storage and CO2 emission of roselle fiber utilized into industrial applications

The research adopted the model of which designed to calculate carbon stored in natural fiber utilized into composite applications.

Carbon stored in fibre=(fiber production ton/ha)*(percentage of processed fibre output)* (1.27+1.835). The three scenarios of roselle fiber production (10; 12 and 15 ton/ha) has been considered in this calculation depending on the average weight of dry matter of roselle fiber.

The analysis depicted that, the weaving blended roselle and aramid fibers used for manufacturing technical texstile is viable financially and the NPV, ROI, IRR as financial indicators also showed high values. The study concluded that, roselle is an important crop to be cultivated for producing fiber utilized into industrial applications. Due to the carbon stored in core and bast when they used together. So, the utilization of roselle whole stem in industrial product is highly encouraged to take place. The study concluded that, research in roselle core and bast usage in industrial applications is highly needed, to assess the impact of roselle cultivation and fiber utilization on the environment.

Business and Economics Journal received 6451 citations as per Google Scholar report