Research Article - (2020) Volume 10, Issue 3

Received: 23-Jan-2020

Published:

07-May-2020

, DOI: 10.37421/2165-8064.2020.10.408

Citation: Onuegbu GC, Nnorom OO, Okonkwo Samuel Nonso and Ojiaku PC. “Diaper Design for Polyester Fabric.” J Textile Sci Eng 10 (2020). doi: 10.37421/jtese.2020.10.408

Copyright: © 2020 Nonso S. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Knowledge about the indigenous traditional woven fabrics of Nigeria reveals the extent the people have advanced in the area of weaving and clothing need. Unfortunately, the indigenous weaving culture faces threat of extinction due to the introduction of machine made fabrics. Here, double twisted and single twisted polyester yarn was used as warp and weft respectively to weave a diaper design for polyester fabric which was used for interior decoration. The diaper weave was produced using a four-shaft hand loom and the steps involved were warping, beaming, heddling or drafting, reeding/denting, tie-up/gaiting, shedding, picking and beating up. The woven diaper polyester was cut and sewn for interior decoration. The diaper twill weave design produced has a front and a back side and was found to be durable, attractive and reliable. Soiling and stains were less noticeable on the uneven surface of the diaper designed twill weave than on a smooth surface, such as plain weaves and as a result makes them suitable for sturdy work clothing, draperies/curtains, durable upholsteries and furnishings. The fewer interlacing in this design as compared to other weaves allow the yarns to move more freely, and therefore they are softer and more pliable, and drape better than most plain-weave textiles. This design also recovers from creasing better than plain weaves do.

Diaper design • Weaving • Polyester • Warp • Weft • Interior decoration

Textile is a broad term referring to any material that can be made into fabrics by any method of construction such as weaving or interlacing, felting and knitting. Textiles play an important role in our life. Everyone in the world is surrounded by textiles from birth to death [1]. Textiles; their function and meaning can vary considerably from culture to culture. But in every culture the way in which a person is clothed, the type of fabric used, its color and patterns speaks to the identity of the wearer, including to his age, gender, social position and role within the community [2].

A textile is a flexible woven material consisting of a network of natural or artificial fibres often referred to as thread or yarn. The yarn is produced by spinning raw fibres of wool, flax, cotton, or other material to produce long strands. Textiles are formed by weaving, knitting, crocheting, knotting, or pressing fibres together. The word fabric is used in textile assembly trades (such as tailoring and dressmaking) as synonyms for textile. However, there are subtle differences in these terms in specialized usage. Textile refers to any material made of interlacing fibres. Fabric refers to any material made through weaving, knitting, spreading, crocheting, or bonding that may be used in production of further goods (garments, etc) [3].

Textiles cover many categories of human want and need. Modern manufacturers distinguish apparel textiles for the body from the coverings of walls and furniture. Hand-made cloth supplies equally varied domains. Within each domain, some fabrics meet practical demands while others communicate meanings or express artistic taste [4].

Textile design associates itself in making creative, stylish and contemporary designs. Textile design requires special skills to create innovative designs. The core of textile designing is concept of designing fabric by using different techniques comprising printing, weaving, ornamenting fabric, print technique, tracing embroidery and colour detailing. It also provides support to clients to visualize the design and to assist them to correct samples while executing prototypes [5].

Textile designing is a creative field that includes fashion design, carpet manufacturing and any other cloth-related field. Textile design fulfills a variety of purposes in our lives. For example, our clothing, carpets, drapes, towels, and rugs are all a result of textile design [6]. Textile designers marry a creative vision of what a finished textile will look like with a deep understanding of the technical aspects of production and the properties of fiber, yarn, and dyes [7].

The creative process often begins with different art mediums to map concepts for the finished product. Traditionally, drawings of woven textile patterns were translated onto special forms of graph paper called point papers, which were used by the weavers in setting up their looms. This paper investigates the use of handloom to produce woven samples with identified yarns and structures for diaper fabric designs.

Materials

The major material used in this research work is the 100% polyester yarn, one which is green in colour and has a double twist while the other is navy-blue polyester yarn with a single twist that was wounded in the shuttle. It was sourced from Onitsha main market, Anambra state.

Sample preparation method

Weft preparation The bobbin winder was used for winding the threads onto the bobbins which are then slotted into the shuttle. A substantial amount of tension is needed when winding the weft onto the bobbins since the absence of this will cause sloughing- off during shuttle traversing.

Warp preparation: The warp yarns run in the lengthwise direction in a woven fabric. These set of yarns are subjected to relative tension that assists in creating a shed during the process of weaving. The various processes these yarns go through before weaving are quite numerous. Because of the stresses and tensions of the warping processes, yarns chosen for warp must have enough strength to withstand the various tensions and stresses they will be subjected to during the actual weaving process.

The warp yarns are prepared through the following processes and in the order outlined below.

1. Warp calculation/Weft Calculation,

2. Milling/Warping,

3. Raddling and Beaming,

4. Heddling/Drafting,

5. Reeding/Denting,

6. Tie-up/Gaiting.

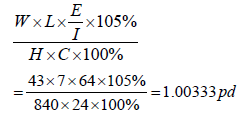

The metric system of calculation could not be used in this project because the number of the reed size is in inches which needs to be converted to the metric system in centimeters but for convenience in calculating, the inches was maintained. The following are the fabric dimensions used for diamond design fabric:

Length of warp, L=7 yards,

Width of cloth in reed W=43inches,

Ends per inch

Picks per inch

Yarn count, C=24,

Hank of the yarn, H=840 yards,

Estimated yarn waste in %=5,

The formula used to express quantity of warp yarn calculation is:

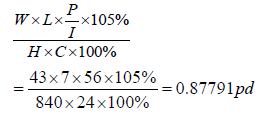

Using the same fabric dimensions above, the weft yarn calculation is expressed below:

This is the quantity of the fibre for the weft in this research work. Add the warp and weft quantity; we will get the total quantity of the fibre yarn used for producing the diamond design fabric.

1.00333 + 0.87791=1.88124pd.

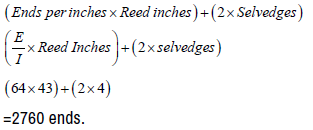

In order to ascertain the required width of the fabric, the total number of ends is calculated. The reed size is multiplied by the predetermined width of the fabric to be woven to obtain the number of ends required for the fabric. The ends for the selvedges are also added to the total ends. In this project, 2 inches was added as selvedges which increased the width and again checked width shrinkage. This is mathematically represented below:

Warping

Before the warping process, the polyester yarns were arranged on the floor in rolls and the individual yarn strands were picked up in two’s and arranged in a certain pattern on the magazine. The magazine is a horizontal framework that helps at the initial stage to guide the researcher in placing of the warp yarns so they don’t entangle. The arrangement is done in a pattern that should be maintained consistently by the researcher. It could be a movement of upwards-downwards or downwards-upwards; same results and aim will be achieved. Since one-colour warp yarns are used, the direction of movement does not matter but it does matter in a two-colour work.

After this arrangement is done successively, the yarns are picked up with a drawing hook and passed through the picking reed. The next stage is passing the warp yarns through the guiding reed and tying them up on the warping drum; a lease thread (black and yellow) was passed through the tie-up done on the drum to ensure separation during warping is maintained; the guiding reed is found on the warping drum. The essence of both reeds is to figure out easily a warp yarn that could be broken in the process. The crosses responsible for shedding are also created during the process. Warping is the process of winding the warp threads around the warper in a rope form. This is done with a predetermined length with the calculated number of total ends which determines the width of the fabric to be woven. The warping drum contains a recorder that keeps record of the number of revolutions the 30 yards of material is warped which equals to 12 revolutions. During warping, the recorder stops movement when the revolution is reached.

Beaming

Beaming follows immediately after warping. The warp ends were then wound onto the warp beam. As the warp yarns were being wound onto the warp beam, beaming sticks were inserted at intervals to separate the warp layers from one another. This activity prevented the yarns from entanglement and again, assisted the operation of warp let-off during weaving. The success of any weaving depends heavily on the beaming process. During the beaming exercise, if the warped yarns are not properly tensioned, some portions of the warp beam will sag and lag during the weaving process proper. This will immediately affect the shading of the warp and so much time will have elapsed due to poor beaming. This research work was beamed successfully by the researcher.

Heddling/drafting

Heddling can be described as the main frame of the weave structure. It determines the order and movement of the upper and lower warp sheets which results in the creation of a shed. This process is also known as drafting. The warp ends were individually passed through the heald’s eye on the various shafts according to a certain order known as the heddling order. A heddling hook was used for this process. It is easier for two persons to do the heddling, one positioned in front and the other behind the loom. The one behind the loom takes the yarns and passes it through the heald’s eye and the one behind draws it through. The drafting started with four ends per heddle for four times at the end (selvedges) while the body is drafted by two ends per heddle. With reference to Figure 1, the order is /1234/ which means the first end was passed through the first heald’s eye on shaft 1. The next end was also passed through the first heald’s eye on shaft 2. It must be noted that, these numerical orders represented the shafts on the loom. In relation, all ends that had the same number were heddled on the successive heddle’s eye on the same shaft (Figures 2 and 3).

Reeding/denting

The completion of the reeding process determines the width of the fabric. The reed size used is 32 inches but the work size is 64 ends/inch. The individual warp ends were passed through the dents of the reed. The ends for the selvedges were plied to strengthen the edges of the fabric. After drafting comes the denting stage and at this stage the drafted yarns are drawn through the dents of the reed using a reeding hook. One should be careful when selecting the next dent so as not to skip dents before drawing through the next dent. The yarns are dented in four’s including the selvedge until complete. This is done to achieve selvedge and to accommodate the work size across the length of the loom [8].

Tie-up/gaiting

This process is identified in two stages. The first process explains tying the ends to the apron stick of the cloth beam. The ends are taken in reasonable quantities and knotted around the apron stick. The ends are pulled to straighten any sagging yarns and the final tension expected in the warp is imparted during the tying process.

The second process defines connecting the shafts through the lams to their respective treadles. This tie-up describes the connection between the four shafts and four treadles responsible for shed creation. It must be noted that, the tie-up arrangement can be changed depending on every fabric’s stepping order. The tie-up is shown below (Figure 4).

The arrangement of the tie-up stage for the diaper design illustrated below describes the movement of the various shaft combination and how they are connected to the treadles during weaving process.

Shaft 1 and 4=Treadle 1

Shaft 1 and 2=Treadle 2

Shaft 2 and 3=Treadle 3

Shaft 3 and 4=Treadle 4

In Figure 4, the vertical bars going upwards represent the shafts in numerical order whereas the horizontal bars going in the right direction indicate the treadles. The tie-up indicates that, whenever a treadle is depressed, the connecting shafts move up and the remaining shafts stay down. For instance, if treadle 1 is depressed, shafts 1 and 4 will go up leaving shafts 2 & 3 to stay down to create the shed for the design. They are called risers and fallers. This explains the rest of the tie-up arrangement.

The diaper twill weave design produced has a front and a back side, unlike plain weave, whose two sides are the same. The front side of the twill is called the technical face and the back the technical back. The technical face side is the side with the most pronounced wale; it is usually more durable and more attractive, is often used as the fashion side of the fabric, and is the side visible during weaving (Figure 5).

Soiling and stains are less noticeable on the uneven surface of this diaper designed twill weave than on a smooth surface, such as plain weaves and as a result makes them suitable for sturdy work clothing, draperies/ curtains, durable upholsteries and furnishings.

The fewer interlacing in this design as compared to other weaves allow the yarns to move more freely, and therefore they are softer and more pliable, and drape better than most plain-weave textiles. This design also recovers from creasing better than plain weaves do (Figure 6).

In this modern age, weaving is undertaken by highly mechanized processes. Majority of furnishing fabrics are produced with foreign designs and imported into the country today. They are all woven by the Jacquard or the Dobby looms. However, studies have shown that diaper twill designs can be woven using the handloom.

In order to obtain the viability of the project, the following objectives were outlined; to identify and explore suitable weave structures for furnishing and drapery fabrics using the broadloom and to assess the suitability of the woven structures for these fabrics. Comprehensive reviews were made on the conceptual and theoretical framework for the study. This was followed by the production of the weaves which were basically studio oriented to produce the fabric sample.

A systematic outline of the preparation and production processes of the sample of the study is also presented. Again, the study provides the aesthetical and functional values of the woven sample. It finally presents discussions of results obtained from the woven sample and appreciation of what was produced.

Journal of Textile Science & Engineering received 1008 citations as per Google Scholar report