Review Article - (2021) Volume 0, Issue 0

Received: 15-Sep-2021

Published:

07-Oct-2021

, DOI: 10.37421/bset.2021.S1.005

Citation: Norimitsu Ichikawa and Satoshi Sakaue. "Epidemiology of Rate of Fatality Due to Electric Shock, 2015-2017." J Biomed Syst Emerg Technol S1 (2021): 005.

Copyright: © 2021 Norimitsu Ichikawa, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

An electric shock accident may occur when a part of the human body touches a charged object, while performing electrical maintenance and replacement activities. This accident can cause an electrical injury, which would require rest and absence of more than 4 days from work, or a fatality. The total number of electrical fatalities from 1959-2017 is 7635 in Japan. The number of electrical fatalities in 2015, 2016, and 2017 were 11, 11, and 9, respectively. Hence, it is necessary to find measures to eliminate electrical fatalities to prevent the unnecessary loss of human life. However, it is challenging because most fatalities occur in construction and manufacturing units. In this study, we evaluated the electrical fatalities between 2015 and 2017. These results will aid in establishing preventive measures for electrical fatalities in the future.

Electric shock • Electrical fatal accident • Preventive measure • Electrical installation

The installation of electrical power receiving equipment is useful in buildings and power plants. However, such an installation could cause an electric shock accident [1-37]. Although there are some improvements in the installation units and preventive measures, this type of electric shock accident has never been eliminated. This may be because the preventive measures for electric shock accidents differ in each country. For example, utility power poles in Japan have cables covered by an insulating material. However, utility power poles in Auburn, USA, have cables without an insulating material [37].

When a part of the human body approaches a charged object of an electrical installation in buildings or plants, an electric shock accident can occur, and the amount of electric current flowing through the human body increases with an increase in the voltage of the charged object. If the human body touches a charged object of 100 V, and has a resistance of 500 Ω, then the electrical current flowing through the body is 200 mA [35].

If an electric current of more than 50 mA flows for 1 s from the left hand to both feet of the human body, ventricular fibrillation can occur. However, the rate of fatality due to ventricular fibrillation because of an electrical accident has been decreasing over the years. This is because of the implementation of enhanced safety measures during maintenance work, and the establishment of a safe maintenance workplace by enforcing the Industrial Safety and Health Act and the Industrial Safety and Health Regulation. We expect that the annual number of fatalities due to electric shock will drop to less than 10 in the near future.

Since cables in Japan are covered by an insulating material, an electric shock accident rarely occurs only when there is a current leakage or the insulating material is old. However, bare cables are commonly used in Auburn, USA, making electric shock accidents likely in the city. Power transmission lines in Japan may sometimes use bare cables. When the jib of a crane approaches one of these transmission lines, an electrical discharge can occur between them, and anyone who touches the crane may experience an electric shock. In Japan, a human generally only comes in contact with a power transmission line during the replacement of an insulator. A secondary disaster can occur in this situation due to an accidental fall because of the voltage induced by the electrostatic induction of the transmission line.

Educational institutions need to teach safety standards related to electric shock accidents, because most electrical activities are performed by parents or guardians in a domestic setting, decreasing the opportunity for young ones to learn. Hence, safer electrical installations, which do not cause electric shock accidents even when touched, are required. However, a human may touch a charged object of a transformer in a cubicle of power-receiving equipment when maintenance work is performed. Improvement of preventive measures while working with bare charged objects of the electrical installation is needed during maintenance activities. Recycled, light weight, insulating materials, such as ping-pong balls, may be better for the insulation gap in these cubicles [38]. Thus, in this study we have evaluated such fatalities and preventive measures to propose valuable inputs, which can be utilized not only in Japan but also the United States. There are only a few such studies. Here, we have considered 31 cases of fatal electric shock accidents, which occurred between 2015 and 2017 [39]. The results will be useful in preventing fatalities in the future and save valuable lives.

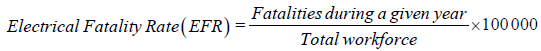

We obtained data on fatalities caused by electric shocks from the Ministry of Health, Labour and Welfare (MHLW) database, and the data on the number of workers (workforce) from the Ministry of Internal Affairs and Communications (MIC) database in Japan. The electrical fatality rate per 100 000 workers can be obtained from the equation (1) (9, 16, 24, 25, 32, 36).

(1)

(1)

Table 1 shows the classification of voltage into low, high, and extra high in Japan.

| Voltage class | AC (alternative current) | DC (direct current) |

|---|---|---|

| Low voltage | V0 ≤ 600 V | V0 ≤ 750 V |

| High voltage | 600 V <V0 ≤7 kV | 750 V < V0 ≤7 kV |

| Extra high voltage | 7 kV < V0 | |

The V0 denotes the value of the voltage of a charged object of the electrical installation.

Figure 1 shows the percentage (electrical death percentage: EDP) of fatalities due to electric shock accidents from 1988–2017 for the occupational accidents.

An electric shock injury was defined as an accident requiring more than 4 days of absence from work. The highest EDP was 28% in 1997. The EDP decreased overall, and became 10% in 2002. Further, the EDPs became 10%, 11%, and 11% in 2015, 2016, and 2017, respectively. The lowest EDP of 4% was recorded in 2013. From the recent trends, one in ten electric shock accidents become fatal.

Figure 2 shows the electrical fatality rates (EFRs) from 1988 to 2017. The EFR decreased overall; 0.017, 0.017, and 0.014 in 2015, 2016, and 2017, respectively. The lowest EFR was observed in 2017, which was 12% of the EFR in 1988. The reasons for the decrease in EFR are as follows:

1) Continuation of electrical safety education.

2) Use of tools and electrical installations to prevent electric shock accidents.

3) Use of robots and drones for electrical maintenance activities.

4) Use of appropriate insulating gloves, plate, and protective equipment.

Figure 3 shows the percentage of fatal accidents caused by the electric shocks from 2015-2017. The results are as follows. The percentage of fatalities due to electric shock accidents is 73% and 9% in the construction and manufacturing, medical, or wholesale industries, respectively in 2015. The percentages of fatalities due to electric shock are 73% and 18% in the construction and manufacturing industries, respectively in 2016. The total percentage of fatalities due to electric shock is 91% in the construction and manufacturing industries and 9% in agriculture industry in 2016. The percentages of fatalities due to electric shock are 56%, 33%, and 11% in the construction, manufacturing, and wholesale industries, respectively in 2017.

The number of the electrical fatal accident is one fatal accident each in 2015 and 2016 though the percentage of the manufacturing industry is different. The one electrical fatal accident of the manufacturing industry is caused by the use of an arc welding machine. The numbers of the electrical fatal accident are 3 fatal accidents in the manufacturing industry in 2017.

The numbers of the electrical fatal accidents in the construction industry are 8 fatal accidents each in 2015 and 2016, and 5 fatal accidents in 2017. Thus, the number of electrical fatal accident in the contact with a live wire in 2017 is lower than those in 2015 and 2016 in the construction industry.

Table 2 shows 11 causes of the fatalities due to electric shocks in 2015. They were electrical wiring and power cable issues, power transmission line and high voltage line issues, arc welding machine, and uncovered charged object issues. When the human body comes in contact with a damaged part or a charged object of the electrical circuitry, or the welding rod of the arc welding machine, fatal accidents due to electric shock can occur. When an arc welding machine is not equipped with a shock prevention device, the voltage of the welding rod becomes approximately 100 V (85 V-95 V). Covering electrical wiring with plastic tape is an inadequate preventive measure and cannot prevent electric shock accidents. Failing to check the voltage of or maintain a safe distance [16] from the high voltage and power transmission line could also cause a fatality by electric shock.

| Case | Cause by electric shock | Voltage class | Industry |

|---|---|---|---|

| 1 | Cutting of electrical wiring by cable cutter | Low voltage | Construction |

| 2 | Damage of insulating cover of electrical wiring | Low voltage | Construction |

| 3 | Replacement of power transmission line | Extra high voltage | Construction |

| 4 | Arc welding machine | Low voltage | Manufacturing |

| 5 | Arc welding machine | Low voltage | Construction |

| 6 | Uncovered charged object of switchboard of dishwasher | Low voltage | Wholesale |

| 7 | High voltage line | High voltage | Construction |

| 8 | High voltage line on scaffolding | High voltage | Construction |

| 9 | Power transmission line | Extra high voltage | Construction |

| 10 | Electrical wiring covered by plastic tape | Low voltage | Construction |

| 11 | Damage of power cable | Low voltage | Medical |

Table 3 shows 11 cases of fatal accident by electric shock in 2016. The causes of fatality were the high voltage and power transmission lines on the steel tower, the live electrical wiring line, arc welding machine, and cubicle. Fatalities caused by the 6600 V high voltage line and the extra high voltage power transmission line occurred through contact between the human body and an uncovered charged object or a leaked current. This is because a cable covered by an insulating material is used for the distribution of the high voltage line; however, the power is transmitted through a bare cable in the extra high voltage line. Fatalities can also occur when the human body touches the ground line connected to the charged object of the live line. Thus, the misconnection of the electrical wiring of an illuminator is caused by insufficient voltage check.

| Case | Cause by electric shock | Voltage class | Industry |

|---|---|---|---|

| 1 | Transmission line | High voltage | Construction |

| 2 | Transmission line for electric-light wiring | High voltage | Construction |

| 3 | Mistake of live line and ground line in illuminator | Low voltage | Construction |

| 4 | Arc welding machine | Low voltage | Manufacturing |

| 5 | Service wire of high voltage line | High voltage | Construction |

| 6 | Arc welding machine | Low voltage | Manufacturing |

| 7 | Pull up connection part of high voltage line | High voltage | Construction |

| 8 | Contact between power line and tree | High voltage | Agriculture |

| 9 | Cubicle | High voltage | Construction |

| 10 | Power transmission line on steel tower | Extra high voltage | Construction |

| 11 | Replacement of parts power transmission line on steel tower | Extra high voltage | Construction |

Table 4 shows 9 cases of fatalities due to electric shocks in 2017. They were the transformer, electrical wiring (power cable), dishwasher, trolley wire, high voltage line, and the fuse of the circuit breaker of the high voltage line. Fatalities occurred when a human body came in contact with a charged object of the transformer in the electric substation, and due to leakage of current from a damaged power cable. Dishwashers have also occasionally caused fatal electric shock accidents. Fatalities have also occurred due to contact between the human body and the trolley wire of the overhead traveling crane, when someone wearing insulating clothes and the insulating gloves was near a high voltage object, and due to a lightning strike.

| Case | Cause by electric shock | Voltage class | Industry |

|---|---|---|---|

| 1 | Charged object of transformer in electrical substation | High voltage | Construction |

| 2 | Electrical wiring of emergency exit light | Low voltage | Construction |

| 3 | Damage of power cable | Low voltage | Manufacturing |

| 4 | Commercial dishwasher | Low voltage | Wholesale |

| 5 | Electrical wiring | Unknown | Construction |

| 6 | Trolley wire of overhead traveling crane | Low voltage | Manufacturing |

| 7 | High voltage line | High voltage | Construction |

| 8 | Fuse of circuit breaker of high voltage line | High voltage | Construction |

| 9 | Lightning strike | Lightning | Manufacturing |

Figure 4 shows the percentage of 11 fatalities due to electric shock by different classes of voltages in 2015. The results reveal that the percentages are 64% for the low voltage and 18% for the high and extra high voltages.

Figure 5 shows the percentage of 11 fatalities due to electric shock by different classes of voltage in 2016. The results reveal that the percentages are 27%, 55%, and 18% for the low, high, and extra high voltages, respectively.

Figure 6 shows the percentage of 9 fatalities due to electric shock by different classes of voltage in 2017. The results reveal that the percentages are 44%, 33%, and 11% for the low, high, and lightning strike or unknown, respectively.

Fatalities can occur due to electric shock. The numbers of workers (workforce) were 76 150 000 workers in 2015, 76 260 000 in 2016, and 76 350 000 in 2017. The electrical fatality rates (EFRs) were 0.017 in 2015, 0.017 in 2016, and 0.014 in 2017. The electrical fatality rate decreased overall, although the number of workers (workforce) increased. This is because of the improvement in preventive measures. For example, maintenance activities were performed using a drone in solar power generation units. A drone and an online monitoring system for current leakage was used in electrical installations. Thus, they were carried out without human contact.

The EDP of the number of fatalities against the number of injuries was 4%– 28% from 1988–2017. The EDP decreased overall. When the EDP is low, the probability of fatalities by electric shock is also low. The EDP can be further reduced by improving safety during maintenance activities.

The construction and manufacturing industries account for 82%–91% of all fatalities caused by electric shocks. Almost all fatal accidents occur in the construction industry. Fatal accidents by electric shock can occur when a human wearing insulating clothes and insulating gloves is near a charged object of a transformer. It can also occur when a human cuts a live line of the electrical wiring with a cable cutter. The lack of a basic voltage check and a safe distance is the cause of fatal deaths caused by electric shock.

Fatalities by electric shock occur when a safe distance (limitation distance) is not maintained between a human body and a high voltage or an extra high voltage charged object. Repeated instruction on maintaining the correct limitation distance is needed.

On low voltage lines, damaged electrical wiring needs to be covered with insulation. This is generally done using cotton work gloves or leather gloves. Table 1 shows the determination of voltage class. The cotton gloves are used in a voltage class of "V0 ≤ 300 Vac and V0 ≤ 750 Vdc" of the low voltage [10]. A worker can use the cotton gloves if such gloves have the dielectric strength in a dry condition without a wet condition as mention above. If the gloves are wet, they occasionally become the cause of the electrical shock accident. Hence, workers should recognize the risk of wearing wet cotton work gloves and leather gloves.

Two fatalities were caused by the arc welding machine in 2015 and 2016. Such accidents occur when the ground of the parent metal is insufficient. The use of an automatic electric shock prevention device is recommended. The use of the voltage checker of an electroscope is recommended for low voltages. A voltage checker should be used by the worker before touching electrical wiring, even if it is a ground line.

Trolley wires must be properly insulated to prevent fatalities through contact with the cabling on overhead traveling cranes. The distribution line in Japan uses everywhere an insulated cable covered by an insulating material. The electrical shock accident occurs occasionally when a worker touches the insulated cable. We can say that the reason is the aging of the insulating cable. When the accident of the insulated cable such as a fire started by a short circuit occurs, the replacement of the aging insulated cable is performed. The replacement of the insulated cable is not performed when the accident of the insulated cable does not occur. It means that the electrical construction industry, for example, in some (or many) companies in Japan does not perform the replacement of a distribution line so far as the electrical accidents of the distribution line do not occur.

A general worker without an electrical engineer does not know the risk of the electric shock accidents though many electrical engineers know the risk. The teaching a basic knowledge between the human body reaction and the human body current is important for many general workers. Many general workers do not know the reason why an electrical spark discharge occurs in a given gap length between a charged object of the electrical installation of high voltage and a human body. The general workers would not know an insulating material though they know that a rubber cannot flow an electrical current. There is some rubber such as an antistatic rubber sheet. The general workers would not determine the insulated rubber sheet or the antistatic rubber sheet. The electric shock accidents are the high risk, and the accident causes occasionally not only the electrical injury accident but also the fatal accident. Such teaching will be helpful for the general worker to prevent the electric shock accidents. These results will aid in establishing preventive measures against fatalities caused by electric shock accidents.

Fatalities can occur due to electric shock. The numbers of workers (workforce) were 76 150 000 workers in 2015, 76 260 000 in 2016, and 76 350 000 in 2017. The electrical fatality rates (EFRs) were 0.017 in 2015, 0.017 in 2016, and 0.014 in 2017. The electrical fatality rate decreased overall, although the number of workers (workforce) increased. This is because of the improvement in preventive measures. For example, maintenance activities were performed using a drone in solar power generation units. A drone and an online monitoring system for current leakage was used in electrical installations. Thus, they were carried out without human contact.

The EDP of the number of fatalities against the number of injuries was 4%– 28% from 1988–2017. The EDP decreased overall. When the EDP is low, the probability of fatalities by electric shock is also low. The EDP can be further reduced by improving safety during maintenance activities.

The construction and manufacturing industries account for 82%–91% of all fatalities caused by electric shocks. Almost all fatal accidents occur in the construction industry. Fatal accidents by electric shock can occur when a human wearing insulating clothes and insulating gloves is near a charged object of a transformer. It can also occur when a human cuts a live line of the electrical wiring with a cable cutter. The lack of a basic voltage check and a safe distance is the cause of fatal deaths caused by electric shock.

Fatalities by electric shock occur when a safe distance (limitation distance) is not maintained between a human body and a high voltage or an extra high voltage charged object. Repeated instruction on maintaining the correct limitation distance is needed.

On low voltage lines, damaged electrical wiring needs to be covered with insulation. This is generally done using cotton work gloves or leather gloves. Table 1 shows the determination of voltage class. The cotton gloves are used in a voltage class of "V0 ≤ 300 Vac and V0 ≤ 750 Vdc" of the low voltage [10]. A worker can use the cotton gloves if such gloves have the dielectric strength in a dry condition without a wet condition as mention above. If the gloves are wet, they occasionally become the cause of the electrical shock accident. Hence, workers should recognize the risk of wearing wet cotton work gloves and leather gloves.

Two fatalities were caused by the arc welding machine in 2015 and 2016. Such accidents occur when the ground of the parent metal is insufficient. The use of an automatic electric shock prevention device is recommended. The use of the voltage checker of an electroscope is recommended for low voltages. A voltage checker should be used by the worker before touching electrical wiring, even if it is a ground line.

Trolley wires must be properly insulated to prevent fatalities through contact with the cabling on overhead traveling cranes. The distribution line in Japan uses everywhere an insulated cable covered by an insulating material. The electrical shock accident occurs occasionally when a worker touches the insulated cable. We can say that the reason is the aging of the insulating cable. When the accident of the insulated cable such as a fire started by a short circuit occurs, the replacement of the aging insulated cable is performed. The replacement of the insulated cable is not performed when the accident of the insulated cable does not occur. It means that the electrical construction industry, for example, in some (or many) companies in Japan does not perform the replacement of a distribution line so far as the electrical accidents of the distribution line do not occur.

A general worker without an electrical engineer does not know the risk of the electric shock accidents though many electrical engineers know the risk. The teaching a basic knowledge between the human body reaction and the human body current is important for many general workers. Many general workers do not know the reason why an electrical spark discharge occurs in a given gap length between a charged object of the electrical installation of high voltage and a human body. The general workers would not know an insulating material though they know that a rubber cannot flow an electrical current. There is some rubber such as an antistatic rubber sheet. The general workers would not determine the insulated rubber sheet or the antistatic rubber sheet. The electric shock accidents are the high risk, and the accident causes occasionally not only the electrical injury accident but also the fatal accident. Such teaching will be helpful for the general worker to prevent the electric shock accidents. These results will aid in establishing preventive measures against fatalities caused by electric shock accidents.