Research - (2022) Volume 11, Issue 11

Received: 02-Nov-2022, Manuscript No. idse-22-79406;

Editor assigned: 03-Nov-2022, Pre QC No. P-79406;

Reviewed: 16-Nov-2022, QC No. Q-79406;

Revised: 17-Nov-2022, Manuscript No. R-79406;

Published:

24-Nov-2022

, DOI: 10.37421/2168-9768.2022.11.359

Citation: Ayala, Gamachu, Bayissa Muleta and Ayana Bulti. “Evaluation of In situ Rain Water Harvesting as an adaptation strategy to climate change for coffee production in Daro Lebu district, West Hararghe, Oromia, Ethiopia.” Irrigat Drainage Sys Eng 11 (2022): 359.

Copyright: © 2022 Ayala G, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Coffee contributes more than 60% of the annual foreign currency and 30% of the government’s direct revenue and the livelihood of 25% of the Ethiopia’s population directly or indirectly depends on the whole value chain of coffee industry. Ethiopian coffee varieties are already well-known, and in high demand by the global market. The most limiting factors to coffee production in Ethiopia are climatic variability, soil moisture stress, poor agricultural practices, prevalence of pests and diseases. The study was conducted to evaluate the effect of in-situ rain water harvesting structures on soil moisture, growth parameters, yield and quality of coffee arabica on two locations at Mechara Agricultural research on-station and Sakina kebele in Daro Lebu district, West Hararghe zone, where moisture stress and low soil fertility are limiting factors. The in-situ rain water harvesting structures used as treatments were Half-moon (semicircular bund), Contour ridge, Negarim micro catchment and normal pit (farmers practice). The treatments were laid out in RCBD with three replications. The data on soil moisture content, growth parameters, yield and coffee bean quality were collected.

Statistical analysis software (R version 4.1.2) was used for data analysis to show mean separation for their significance difference at (P<0.05). Soil moisture content, Plant height, first primary branch, and canopy diameter has highly significance difference at (P<0.05) among the treatments at both site. From the in-situ water harvesting practices Semi-circular bund and Negarim micro catchment had shown the best soil moisture retention at (0-20) cm and (20-40) cm depth among others. The mean coffee quality parameters such as color, overall aromatic quality and Flavor are shown significant difference (P<0.05) among in-situ water harvesting structures by conserving soil moisture under coffee root zone. There is also coffee quality attribute difference between treatments which is the best option for both consumption and market. Among treatments semi-circular bund and Negarim micro catchment structures shown better performance in improving soil moisture stored within the root zone, reduces soil erosion and increase coffee growth, quality and yield of coffee Arabica in moisture stress areas of West Hararghe Zone and similar agro ecologies..

Soil moisture • Coffee • Yield • Climate change • Coffee quality • In-situ water harvesting

Background and justifications

Coffee is the world’s most widely traded tropical product, produced in over 50 developing countries (CAB International, 2016). It is the backbone of the Ethiopian economy. Ethiopia is birthplace of coffee Arabica, the largest producer of coffee in Africa and is the fifth largest coffee producer in the world next to Brazil, Vietnam, Colombia, and Indonesia, contributing about 7 to 10% of total world coffee production [1]. In Ethiopia, the estimated coffee planted produced accounts 525,000 hectares (5,250 km2). Around 70% of Ethiopian coffee production comes from Oromia region where different coffee production systems are practiced. Coffee has economic, environmental, cultural as well as social significance to Ethiopia. It provides the country with its most important agricultural commodity, contributing around one quarter of its total export earnings [2]. Contributing 41% of the country’s total foreign exchange earnings [3] and about 10% of the gross domestic product. Variability in local weather and changes in global climate has brought about reduced amount and erratic distribution of the seasonal rainfall, which in turn, resulted in frequent drought incidences in Ethiopia, as well as in most potential agricultural regions of the world [4]. Climate variability factors such as water stress, increased temperatures and carbon dioxide can reduce coffee quality. Currently, the effects of climate change; higher temperatures and less rainfall could take a toll on the country's ability to farm this treasured crop. Ethiopia could lose from 39% to 59% of its current coffee-growing areas due to climate change by the end of the century [5]. Understanding more about the science of these changes can help farmers adapt and improve their coffee production. Many coffeeproducing regions are increasingly experiencing changing climate conditions, whose impact on coffee’s taste, aroma, and even dietary quality is as much a concern as yields and sustainability.

Rain fed agriculture is the dominant form of land use in Ethiopia. The economy of the country is highly sensitive to climate and extreme variability of rainfall intensity and frequency of dry spells. The low soil fertility and moistures stress are the most limiting factors to coffee production in the semi-arid area of Ethiopia [4]. Coffee from the eastern part of Ethiopia is known for its Mocha flavour and fetches premium value on the world market. The presence of 22 promising landraces and four released Hararghe coffee varieties are good opportunities to improve coffee quality and cross for different traits including drought tolerance. Hararghe coffee is despite its economic importance in the world market and in the national economy of Ethiopia; its productivity is very low primarily because of periodic soil moisture deficit stresses and many other factors. Harar area is typically affected by moisture stress. Harar coffee contributes about 10% of the Ethiopia’s total coffee acreage and 8% of its coffee export [6,7]. Smallholders cultivate more than 70% of global coffee production. More secure livelihoods and a higher quality of life may be possible for many smallholder farmers if they are able to grow a more sustainable and secure coffee crop.

Farmers of the area grow coffee landraces having their own characteristic features [8]. The region has favourable agro-ecological and socio-cultural conditions for coffee production. Despite the immense potential, productivity and quality of coffee production in the region remained low. The average coffee productivity in the area is 512 kg/ha which is below the national average [9]. Western Hararghe is one of the most drought prone areas of the Oromia Regional State, Ethiopia [10]. As a result of this coffee yield is strongly influenced by lack of soil moisture during growth, flowering, fruit setting, bean synthesis and expansion [10]. Recurrent droughts, mid-season droughts and delayed start and premature end of the season are the major cause of water stress to coffee plants and are responsible for low coffee yield in the areas. Generally, to adapt climate change due to drought or moisture stress and there by improve coffee productivity and quality, developing rainwater harvesting, mulching, soil and water conservation measures, use of improved drought tolerant varieties of crops, integrated pest management, soil moisture conservation and nutrient managements are the main interventions in integrated manner or solely. The benefits of in-situ water harvesting are reduction in runoff and erosion and increased infiltration and storage of water in the soil profile which delay the onset and occurrence of severe water stress thereby improving the crop against damage caused by water deficits during dry periods. Therefore, In situ rainwater harvestings are believed to counter the negative effects of these factors and strategy for improving coffee quality and productivity in this area. Such measures are very helpful to smallholder farmers in improving their livelihood in moisture stress areas of Eastern part of the country. Therefore, the main objective of the activity was to evaluate effect of In situ rainwater harvesting on soil moisture, growth, quality and yield of coffee in study area.

Description of the study area: The trial was conducted from 2015-2021 at Mechara Agricultural Research Center (on station) and Sakina kebele in Daro Labu district of West Hararge zone, which lies South of Chiro town at a distance of 435km from Addis Ababa and 110 km to the south west direction from zone town. The altitude ranges from 1040 to 1780 m a. s. l. with area coverage of 156,460 ha of land (Ethiopian DEM, 2017). Rainfall pattern in the area is bi-modal; kiremt rainy season (June, January, August and September) and belg rainy season (February, March, April and May). Average annual rainfall amount is 1145 mm. High amount of rainfall is received in the April (188 mm) and May (1395 mm) during the belg rainy season whereas high amount of rainfall is received in the month of July (1180 mm) and August (1462 mm) in the kiremt rainy season. Mean annual temperature is 21°C with mean annual minimum temperature of 13°C and maximum 27°C (Mechara agricultural research center, meteorological station, 2009-2017). Soil of study area is dominantly reddish brown Nitosols. They are generally clay dominated and are characterized by low available phosphorous with a pH ranging from 5.3 to 6 in surface soils. The vegetation cover of the area is woodland and open wooded grassland types (Figure 1).

Treatments and experimental design: Three In-situ water harvesting structures namely; half-moon shaped structure (Semicircular bund), diamond shaped structure (Negarim micro catchment), contour ridges and normal pit (farmers practice) were used as treatments. The randomized block design (RCBD) with three replications was used. The selected coffee variety was Mechara-1 which released from Mechara Agricultural Research center in 2010. The In-situ water harvesting structures were prepared according to the standard dimension considering all design criteria. The pits dimension of (60 cm x 60 cm) with a depth and width respectively were dug in prepared structure to transplant a coffee in it. The coffee spacing of 2 m x 2 m inter row and intra plant was used on plot area of 5.3 x 7 m. The contour ridges were prepared in dimension of 60 cm width of furrow, 20 cm berm and 50 cm width of ridge, Half-moon and Negarim micro catchment with 1.3 m diameter and 0.5 m between two bunds are used. The coffee seedlings were transplanted in pits prepared in the structures. The normal pit was used as farmers practice and the recommended fertilizer was used according to stage of coffee plant.

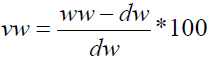

Data collection: The coffee growth and yield data parameters such as plant height, girth, nodes per primary branch, number of internodes, canopy diameter, coffee bean quality and yield were collected. Physicochemical soil properties such as soil moisture and chemical nutrients in soil were also collected. Composite soil samples were collected for moisture determination at depth of 0-20 cm and 20–40 cm using auger. The soil samples were collected and analyzed for pH(by H2O 1:2.5), texture(by Hydrometer Method), Available P (by Olsen method), Available K (by Ammonium Acetate Method 1MNH4OAC) and total N% (by Kjeldahl Method), CEC(by Ammonium Acetate Method 1MNH4OAC) and organic carbon(by Walkely and Black method). The soil moisture content data collected were determined using gravimetric method as formula below.

Where: Vw = is volumetric water contents, ww= is soil wet weight and dw = is soil dry weight

Coffee bean quality analysis and sampling procedures

Coffee cherries drying and packing: The oldest and simplest method producing’ natural’ coffee is ‘sun drying’ that has been adopted throughout all coffee growing areas in Ethiopia, and this system was the only processing method. The cherries were spread out evenly on mesh wire to dry in the sun. Each sample cherries were dried until the recommended moisture content of 11-12% was attained. Then after, the sample cherries were hulled with mortar as farmers have been practicing carefully and cleaned. Finally, the green coffee beans were labelled and packed in transparent polyethylene bags where berries stabilize their moisture content and quality attribute. The packed dry coffee bean was then transported to Jimma Agricultural Research Center for determination of the raw and cup coffee quality. The packed and collected samples were prepared using proper method of processing and arbitrary code (identity letter) was assigned to secure unbiased judgment. The packed dry coffee bean samples were transferred to coffee quality laboratory at Jimma Agriculture Research Center to evaluate the quality, based on the physical, raw, aroma and cup attributes.

Screen size of coffee beans: Bean sizes were determined by conventional screen analysis of perforated plate screen sizes of 14 with respective whole diameter of 5.55 mm (Wintgens, 2009). 300g of each coffee samples were replicated three times and measured using digital beam balance. The coffee beans were graded by size using standard screen that have different screen size, with ‘round holes’ as defined by (ISO, 1991). The normal sizes of coffee beans were remained over the screen in order to determine their normality percentage while undervalued and broken beans were separated from each sample. Finally, the defect count percentage was recorded as per national fixed standard.

Raw coffee quality grade evaluation: During physical quality analysis; 300g of green bean was used for each sample for their qualities attribute such as ‘shape and make’, colour and odour. These quality attributes were measured according to the Ethiopian standard that based on raw quality parameters’ grading was done in account of 40% as per ECX, 2009.

Aroma and cup quality grade evaluation: Three cups per treatment in three replications were prepared for each tasting session. The evaluation had been carried out by a panel of Jimma Agricultural Research Center panelist who formed a team of trained, experienced and certified quality graders and cuppers in order to get aroma and cup quality values in account of 60%. In this case, three experienced tasters participated in a panel to evaluate coffee bean samples’ aroma and taste characteristics of each treatment of coffee brew involving olfaction, gestation, and mouth feel sensation. For each sample using the round soup spoon raise six to eight cc of liquid to just in front of the mouth and forcefully slurp the liquid. Aroma was evaluated by sensation from brewed coffee that released gasses. The released gasses were inhaled through the nose by sniffing and briskly/quickly aspiring, the coffee. In this way, spread evenly over the entire surface of the tongue. Sensory evaluation was done using the following quality criteria in scale range of (AI, AQ, AC, AS, BI, BD, FL and OAQ) value. Based on these measures, the scale comprised the point ranged from 1-15 was used. The sensation was obtained from the gases released from roasted and ground coffee beans as aromatic compounds. In order to evaluate sample of ground coffee quality, the gasses were inhaled through the nose with sniffing/smelling aroma and the inhaling process revealed the nature of coffee bean taste/typicity such as flavor, mocha, spicy, etc.

Data analysis: The collected data were analyzed by using R version 4.1.2 for analysis of variance (ANOVA) was used and the mean separation using LSD was used at 5% significance level.

The growth parameters such as length of primary branch, canopy diameter and yield (Q/ha) shown significant difference (P<0.05) among in-situ water harvesting at Sakina in 2019/2020. While the other parameters were not shown significant at (P<0.05) level among the treatments. The significance those seen on coffee growth and yield components were due to soil moisture difference between different in-situ water harvesting structures (Table 1). This is agreeing with the work of Admasu T, et al. [11]. Canopy diameter north to south, length of primary branches and nodes shown significant difference at (p<0.05) among in-situ water harvesting structure at Mechara on station in 2019/20 cropping season. It shows that as canopy diameter increase, length of coffee branch also increase which directly affect the coffee yield. Depend on their significance level the highest value was obtained on contour ridge followed by semi-circular bund. The first longest primary branch, canopy diameter and the nodes reveals significance difference (p<0.05) levels due to soil moisture difference between treatment structures (Table 2). which was the highest value recorded on contour ridge followed by semi-circular bund. On some coffee growth components such as plant height, girth, internodes and primary branch semi-circular bund recorded the highest than other in situ water harvesting structures at on-station. Generally, contour ridge and semi-circular structures shown best performance in terms of all coffee growth parameters and soil moisture conservation at on-station. So that, as an option to increase coffee production as well as soil moisture conservation, contour ridge and semi-circular bund structures were the best among other alternative methods.

| Trt | Ph | Gth | LPB | I/node | node | NoPB | EW | NS | 100 Seed wt |

|---|---|---|---|---|---|---|---|---|---|

| SC | 195 | 48.13 | 108.1a | 33.2 | 34.2 | 69.9 | 147.3a | 136.7 | 12.1 |

| CR | 179.7 | 48.93 | 92.7b | 37.9 | 38.7 | 77.3 | 118.0b | 111.3 | 26.3 |

| NG | 195.7 | 47.27 | 106.0a | 33.7 | 34.7 | 78.7 | 136.0ab | 128.7 | 11.7 |

| NP | 187 | 49.27 | 96.0ab | 33.1 | 34.1 | 79.6 | 129.0ab | 117 | 11 |

| Mean | 189.3 | 48.4 | 100.7 | 34.5 | 35.4 | 76.4 | 132.6 | 123.4 | 15.3 |

| Lsd (5%) | 26.7 | 8.13 | 12.4 | 11.1 | 11 | 27 | 28.06 | 25.7 | 23.9 |

| Cv (%) | 7.1 | 8.4 | 6.2 | 16.1 | 15.6 | 17.7 | 10.6 | 10.4 | 78.4 |

| Trt | Ph | Gth | LPB | Inter nod | nodes | pb | EW | NS |

|---|---|---|---|---|---|---|---|---|

| SC | 210 | 43.4 | 113.3a | 30.1 | 31.1a | 63.3 | 147.3 | 147.3ab |

| CR | 198 | 43.4 | 129.1a | 28.8 | 39.7a | 57.1 | 156.3 | 154.0a |

| NG | 197 | 39.4 | 97.6b | 27.1 | 26.9b | 49.2 | 146.7 | 135.3b |

| NP | 196.7 | 42.2 | 96.1b | 24 | 26.7b | 56.1 | 146 | 148.3ab |

| Mean | 200.4 | 42.1 | 109 | 27.5 | 28.6 | 56.4 | 149.1 | 146.2 |

| LSD (0.05) | Ns | Ns | - | Ns | - | Ns | Ns | - |

| Cv (%) | 4.9 | 5 | 20.7 | 18.5 | 15.9 | 16.2 | 8.1 | 5.3 |

Effect of in-situ water harvesting on coffee yield: The results of analysis of variance (ANOVA) of the clean coffee bean yield (q/ha) shown significant difference (P<0.05) among in-situ water harvesting at sakina in 2018/19 due to soil moisture was relatively low during this crop season. During this year semi-circular bund conserve more soil moisture than other in-situ water harvesting; hence, the yield was higher relative to others. The lowest coffee yield was recorded during 2018/2019 cropping season at both Sakina and on-station. This is because coffee yield related climate condition (during this year soil moisture was very low relative to other year). This agrees with work of legesse, 2019 which states, alteration in precipitation patterns, temperature, storms, strong winds and other extreme weather events directly impact coffee quality and productivity levels. However, the results of ANOVA showed non-significant differences (P>0.05) among the treatments on yield parameters, the highest mean yield (q/ha) was recorded on semi-circular bund and Negarim micro catchment at both location during 2020/21 cropping season. As it seen in (Table 3). The overall mean yield advantage recorded on semi-circular bund is 44% followed by Negarim micro-catchment 16.4% compared to farmers practice at Sakina kebele which is not significance difference but has numerical difference. During 2020/21 cropping season. The overall mean yield advantage of both locations on Negarim micro catchment is 18.4% followed by Semi-circular bund by 8.1%. This shows that, even though there was no statistical difference, on the coffee yield there is difference in yield advantage obtained from in-situ water harvesting resulted in sustainable coffee production increases.

| Treatments | Clean bean Yield(q/ha) | ||

|---|---|---|---|

| 2018/19 | 2020/21 | Overall Mean | |

| SC | 7.16a | 19.13 | 13.14 |

| CR | 4.01b | 13.41 | 8.71 |

| NG | 5.69ab | 15.53 | 10.61 |

| NP | 5.23ab | 12.99 | 9.11 |

| mean | 5.52 | 15.27 | 10.395 |

| LSD (5%) | 2.7 | 6.34(Ns) | - |

| Cv (%) | 25.3 | 20.9 | 36.87 |

Effect in-situ water harvesting across site, season and their interaction: The highest coffee yield was recorded on semicircular bund during both seasons at Sakina site, while at Mechara on-station the highest yield observed on contour ridge structure (Tables 3, 4 and 5). The clean coffee bean yield during 2018/2019 was much lower than the second year, this is due to low rain fall as a result low soil moisture during the season or due to characteristic of the coffee at both site. When we say the characteristic of the coffee, this plant is not gave similar yield across the year. The combined mean analysis of coffee bean yield at both site during both season showed, the highest yield observed on Negarim micro catchment and Semicircular bund due to high the soil water holding capacity is increased. Generally, the result shows both Negarim micro catchment and Semicircular bund performs well in terms of coffee bean yield.

| Treatments | Clean bean Yield(q/ha) | Overall mean | |

|---|---|---|---|

| 2019/20 | 2020/21 | ||

| SC | 9.48 | 13.30 | 11.40 |

| CR | 10.25 | 20.00 | 15.13 |

| NG | 8.05 | 11.80 | 9.90 |

| NP | 8.11 | 17.00 | 12.56 |

| mean | 8.97 | 15.50 | 12.24 |

| Cv (%) | 23.40 | 44.40 | 33.90 |

| LSD (5%) | 4.19(ns) | 13.80(ns) | 9.00 |

| Treatment | On station Yield(q/ha) | Sakina Yield(q/ha) | Overall mean |

|---|---|---|---|

| SC | 13.3 | 19.13 | 16.22 |

| NG | 20 | 15.53 | 17.77 |

| CR | 11.8 | 13.41 | 12.61 |

| NP | 17 | 12.99 | 15 |

| Mean | 15.5 | 15.27 | 15.4 |

| LSD (0.05) | 13.8(Ns) | 6.34(Ns) | - |

| CV (%) | 44.4 | 20.90 | - |

Effect of in-situ water harvesting on soil moisture contents and soil physico chemical properties: The composite soil sample characterized by physicochemical analysis result as shown below (Table 6). The physicochemical properties laboratory analyses of the area are characterized as above (Tables 6 and 7). The pH ranges from (6.39-6.62) which categorized as slightly acidic to neutral soil which is optimum for coffee production. The soil texture is sandy loam soil. The organic carbon ranges from 0.22-0.44 percent. The highest organic carbon was observed on Negarim micro catchment, this is due to improved soil physical environment particularly water holding capacity, which in turn increased the soil biota activity led to enhanced decomposition of organic material rapidly. The cation exchange capacity of soil (CEC) parameter ranges from 20-22.18 meq/100 g, this range is categorized as moderate based on CEC rating [12]. The CEC is a major controlling agent of stability of soil structure and nutrient availability for plant growth. The highest mean CEC parameter observed on semi-circular bund with value of 22.18 shows there is high exchange of nutrients in the soil due the soil water holding capacity is improved as a result microorganisms’ found in the soil performs well, as well as soil fertility is high.

| Trt | PH (H2O) | TN (%) | P (ppm) | K (ppm) | CEC (meq/100g) | OC (%) | Texture |

|---|---|---|---|---|---|---|---|

| NP | 6.62 | 0.03 | 9.34 | 31 | 20.79 | 0.30 | Sandy loam |

| NG | 6.39 | 0.04 | 9.9 | 35.5 | 20.39 | 0.44 | Sandy loam |

| SC | 6.44 | 0.02 | 9.36 | 44.5 | 22.18 | 0.24 | Sandy loam |

| CR | 6.56 | 0.02 | 6.68 | 35.5 | 20.00 | 0.22 | Sandy loam |

| TRT | Raw Quality 40% | Liquor Value quality (60%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sh/m | Co | Od | AI | AQ | AC | AS | BI | BO | FL | OAQ | TQ | |

| SC | 12.8 | 12.3ab | 9.8 | 4.13 | 4.17a | 8.13 | 4.47 | 4.53 | 8.1 | 8.17** | 8.22a | 84.9** |

| CR | 12.6 | 12.6a | 9.9 | 4.06 | 4.13a | 7.8 | 4.37 | 4.03 | 7.77 | 7.61b | 7.68b | 82.62b |

| NG | 12.1 | 12.1b | 9.9 | 4.1 | 3.73b | 7.67 | 4.17 | 4.2 | 7.7 | 7.72b | 7.69b | 81.52b |

| NP | 12.4 | 12.3ab | 9.9 | 4.1 | 4.03ab | 7.86 | 4.27 | 4.4 | 7.73 | 7.70b | 7.76ab | 82.42b |

| Mean | 12.6 | 12.34 | 9.92 | 4.1 | 4.02 | 7.87 | 4.32 | 4.3 | 7.82 | 7.8 | 7.84 | 82.87 |

| CV | 5.16 | 1.4 | 1.2 | 2.9 | 4.87 | 4.17 | 9.36 | 7.13 | 2.9 | 2.3 | 3.27 | 1.2 |

| Lsd | 0.86 | 0.05 | 0.86 | 0.92 | 0.09 | 0.4 | 0.82 | 0.27 | 0.2 | 0.02 | 0.09 | 0.02 |

The soil moisture parameter is the most important parameters in moisture stress areas. The effects of in-situ water harvesting on soil moisture content are shown (Figure 2). The lower soil moisture content was found on normal pit (NP) at both 0-20 cm and 20-40 cm depth of soil. The highest soil moisture content was found on both semi-circular bund (SCMC) and Negarim (NG) at 20-40 cm soil depth. The highest soil moisture content was founded on semicircular bund (SCMC) and minimum was obtained on NP at 0-20 cm depth at both sites. In general, there is direct relationship between soil moisture parameter and coffee yield obtained. In-situ water harvesting structures showed that high soil moisture content was observed on semi circular bund 17.8, followed by contour ridge 17.5, Negarim micro catchment 17 and Normal pit 16.2 in percentage at 0-20 cm soil depth.

Generally, soil moisture content on all structures at 20-40 cm depth is higher than 0-20 cm because, as depth increase, soil moisture increase. This result support work of legesse, 2019 In-situ water harvesting practices reduce soil erosion and increase water holding capacity of soil as a result improve coffee bean yield and further help farmers adapt to climate change and retain the more fertile topsoil [13]. This result also agreed with Mudatenguha F, et al. [14] and Karrar AB, et al. [15]. In-situ water harvesting structures can improve soil moisture storage, prolong the period of moisture availability, enhance the growth of crops and crop yield.

Effect of in-situ water harvesting on coffee quality parameters: There are two categories of coffee quality attributes; raw quality (40%) and liquor value quality (60%). Coffee raw quality parameters (40%) includes shape and make(15%), Colour (15%) and odour (10%) while Liquor coffee quality parameter(60%) includes Aromatic intensity(5%), Aromatic quality (10%), Acidity (5%), Astringency (5%), flavour(5%) and bitterness(5%) etc. The mean coffee quality parameters such as colour, overall aromatic quality and Flavour are shown significant difference (P<0.05) among in-situ water harvesting structures (Table 6). This shows in-situ water harvesting structures improve coffee quality by conserving soil moisture under coffee root zone in moisture stress areas [16-20]. The highest mean coffee quality parameters are recorded on semi-circular bund among other in-situ water harvesting structures. So, the coffee producer could be increasing the coffee prices by adding coffee quality level by implementing in-situ water harvesting structures on their farmlands. Increasing coffee quality is not improve only local prices, but also improves international coffee market, So that, using in-situ water harvesting structures is the best alternative for increasing coffee production and quality in a sustainable way as well as improve small holder farmer’s income. In addition, in-situ water harvesting structures are used as climate adaptation and mitigation strategies in moisture stress and coffee growing areas of our country [21-25].

Rain fed agriculture is the dominant form of land use in Ethiopia. The economy of the country is highly sensitive to climate and extreme variability of rainfall intensity and frequency of dry spells. The low soil fertility and moistures stress are the most limiting factors to coffee production in the semi -arid area of Ethiopia. Ethiopian coffee production become deteriorates from time to time because of daily and annual climatic variation. In-situ water harvesting are considered as climate mitigation and adaptation techniques where the fluctuation of climate in the coffee growing area resulted in reduction in the yield and quality, increasing the outbreak of pest disease, increasing cost of production and reduced area of production. In-situ water harvesting practices reduced soil erosion and increased water retention as a result help farmers adapt to climate change and retain the more fertile topsoil. Even though, there is no significance difference (P>0.05) on yield parameters, the highest mean coffee yield recorded on semi-circular bund and Negarim micro catchment at both location during 2020/21 cropping season. The yield advantage recorded on semi-circular bund is 44% followed by Negarim micro-catchment 16.4% compared to farmer’s practice which is not significance difference but has numerical difference. The mean coffee quality parameters such as colour, overall aromatic quality and Flavour are shown significant difference (P<0.05) among in-situ water harvesting structures. This shows in-situ water harvesting structures improve coffee quality by conserving soil moisture under coffee root zone in moisture stress areas. The highest mean coffee quality parameters are recorded on Semi-circular bund among other in-situ water harvesting structures. Increasing coffee quality is not improve only local prices, but also improves international coffee market, So that, using in-situ water harvesting structures is the best alternative for increasing coffee production and quality in a sustainable way as well as improve small holder farmer’s income. In addition, in-situ water harvesting structures are used as climate adaptation and mitigation strategies in moisture stress and coffee growing areas of our country.

From these In-situ water harvesting structures based on result; semicircular bund and Negarim micro catchment shown better performance in terms of improving soil moisture stored within the root zone as well as coffee growth parameters, quality attributes and yield of coffee Arabica in moisture stress areas of west Hararghe zone and similar agro ecologies. In-situ water harvesting application as climate adaptation mechanisms ensures high quality and sustainable production of coffee and also maintain sustainable ecosystem. In addition, these technologies are feasible and cost effective for smallholder farmers for practically implements to improve their coffee production and productivity.

The authors express their gratitude to the staff of Soil Water Conservation and Watershed Management and Coffee Improvement Research team of Mechara Agriculture Research Centre for their follow- up and data collection and Oromia Agricultural Research Institution for its financial support. In addition, our thanks go to Jimma Agricultural Research Center (JARC) for supporting us by analysing coffee bean quality and Batu Soil Research Center (BSRC) for soil physicochemical analysis.

Irrigation & Drainage Systems Engineering received 835 citations as per Google Scholar report