Opinion - (2022) Volume 12, Issue 12

Received: 01-Nov-2022, Manuscript No. jbpbt-22-78828;

Editor assigned: 03-Nov-2022, Pre QC No. P-78828;

Reviewed: 15-Nov-2022, QC No. Q-78828;

Revised: 21-Dec-2022, Manuscript No. R-78828;

Published:

28-Dec-2022

, DOI: 10.37421/2155 9821.2022.12.554

Citation: Galiulin, Nakip. “The Advanced Ozonating Mixing Vessel with Agitator.” J Bioprocess Biotech 12 (2022): 554.

Copyright: © 2022 Galiulin N. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Reactions in gas-liquid sistem are one of the methods for carrying out of process at hemical technology. Fo forming such sistem have been developed different constructure of apparatuses among that traditionally has use mixing vessel with agitator and device for gas sparched. Water ozonating is reaction that carrying out in gas -liquid sistem and is employs for clearig natural water at stations of water supply and at installation of utilisation of sewage water. At present time ozanatig of water has industrial development so there is interested for aplication advanced apparatuses.

The proposed apparatus does not have a device for bubbling gas through the liquid to create a gas-liquid layer. The ozone-gas is fed into the upper part of the vessel above the liquid level. This method doesn’t require big volumes of ozone for forming gas-liquid layer in apparatus.

Is proposed the apparatus for ozonation of water in which carry out dissolution of ozone in water by ozone-gas (Figures 1 and 2). With this aim in apparatus introduces ozone-gas into the top of the vessel above the liquid level. The complex with four baffles that have form of plate plunged into layer of water and two disk turbine agitator on shaft makes four swirls. The upper disk turbine has inclined blades with angle incline 45° that direct axial going flow to down. Swirl funnels are forming between baffle. The swirls have ideal natural configuration and continuation tail reaching lower disk turbine. The ozone-gas is sucked down by swirl tubes then is dissipated by (lower) disk turbine into the volume of the liquid with dispersed bubbles formation. In area between disc turbines is arised radial flow that separate liquid from shaft with forming of gas-liquid layer (Figure 1). Such principle of organization of the flows secures multiple of circulation of ozone-gas within the liquid what don't require to spend big quantity of the ozone-gas for producing ozonated water. The design dimensions of the apparatus are summarized in Table 1. There the apparatus diameter is base for design relations.

Notations in the Table 1, the drawing (Figures 1 and 2)

| D | H | H1 | d1 | d2 | h1 | h2 | I | b | c | m | u |

|---|---|---|---|---|---|---|---|---|---|---|---|

| - | 1.5 D | 1.2D | 0.4 D | 0.4 D | 0.4 D | 0.4 D | 0.44 D | 0.16 D | 0.24 D | 0.22 D | 0.11 D |

D― vessel diameter;

H― hight of vessel;

H_1― height of the liquid level in the vessel;

d_1 ― diameter of the disk turbine with straight blades;

d_2―diameter of the disk turbine with inclined blades angle 45°;

h_1―distance from the vessel bottom to the lower disk turbine with straight blades;

h_2―distance between disk turbines;

l―height of baffle immersed in liquid;

(b+c)―baffle width;

1―Liquid inlet;2―Liquid otlet;3―Ozone-gas inlet;4―Gas escape;5― Baffle;6―Rushton disk turbine with straight blades (six blades);7―Rushton disk turbine with inclining of blades -45° (six blades);8―Shaft;9―Vessel lid;

Practice

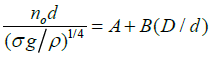

Have been carried out investigations in order to obtain data for the industrial implementation of the proposed construction apparatus. On base of result of investigation have taken on equation defining of the beginning of the intensive aeration threshold [1]:

It’s:

n_0―agitator rotation number (sec) ^(-1));

d=d_1 ―agitator diameter (m);

D―vessel diameter (m);

g=9.81 (m⁄(sec^2))―acceleration of gravity;

ρ―liquid density (κq⁄m^3);

σ―surface tension coefficient (κg⁄(sec)^2);

A=1.22 B=1.25

Table 2 is given the values of the power criterion depending on the working circumferential speed of the agitator. k_N―power criterion;

| kN | 7.6 | 7.3 | 6.9 | 5.8 | 4.01 | 3.4 | 2.93 | 2.5 | 7.6 | 7.3 | 6.9 |

| v | 0.43 | 0.85 | 1.28 | 1.71 | 2.14 | 2.56 | 3.0 | 3.42 | 0.43 | 0.85 | 1.28 |

v―agitator circumferential speed (m∕sec);

v = n0πd1

Is given principal scheme of baffles location to make projecting work (Figure 3).

Thus, by introducing simple constructive changes to the standard apparatus, it is possible to achieve a new principle for creating gas-liquid systems to use surface aeration. What does not require large expenditures when introducing the zonation advanced apparatus at treatment industrial plants of waters.

Journal of Bioprocessing & Biotechniques received 3351 citations as per Google Scholar report